Wholesale Price China Suger Packaging Machine - Organic Fertilizer Round Polishing Machine – YiZheng

Wholesale Price China Suger Packaging Machine - Organic Fertilizer Round Polishing Machine – YiZheng Detail:

1.The bio-organic granulation fertilizer which makes peat, lignite, organic fertilizer sludge, straw as raw material

2.Organic granulation fertilizer which makes chicken manure as raw material

3.Cake fertilizer which makes soy-bean cake as raw material

4.Mixed feed which makes corn, beans, grass meal as raw material

5.Bio-feed which makes crop straw as raw material

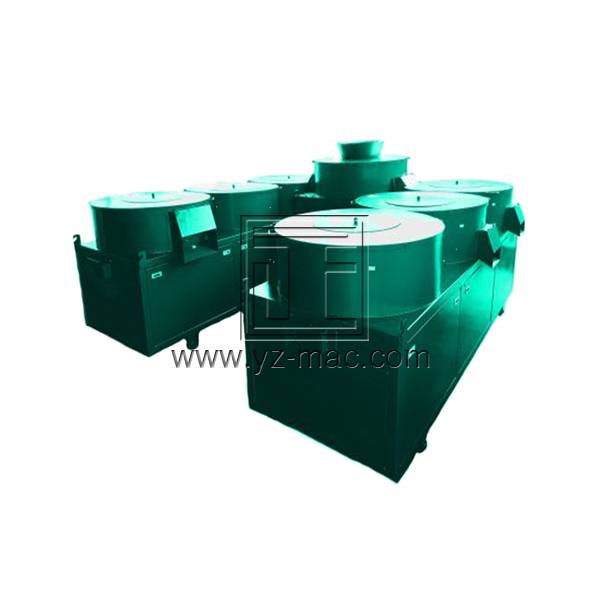

1. High output. It can be flexible worked with one or several granulators at the same time in the process, solving the disadvantage that a granulator must be equipped with a coating machine.

2. The machine is made up by two or more polishing cylinder orderly, the material will be out after several times polishing, the finished product has uniform size, consistent density and nice appearance, and the shaping rate is up to 95%.

3. It has simple structure, safe and reliable.

4. Easy operation and maintenance.

5. Strong adaptability, it can work in various environments.

6. Low power consumption, low production cost and high economic benefits.

|

Model |

YZPY-800 |

YZPY-1000 |

YZPY-1200 |

|

Power (KW) |

8 |

11 |

11 |

|

Disc Diameter (mm) |

800 |

1000 |

1200 |

|

Shape Size (mm) |

1700×850×1400 |

2100×1100×1400 |

2600×1300×1500 |

Product detail pictures:

Related Product Guide:

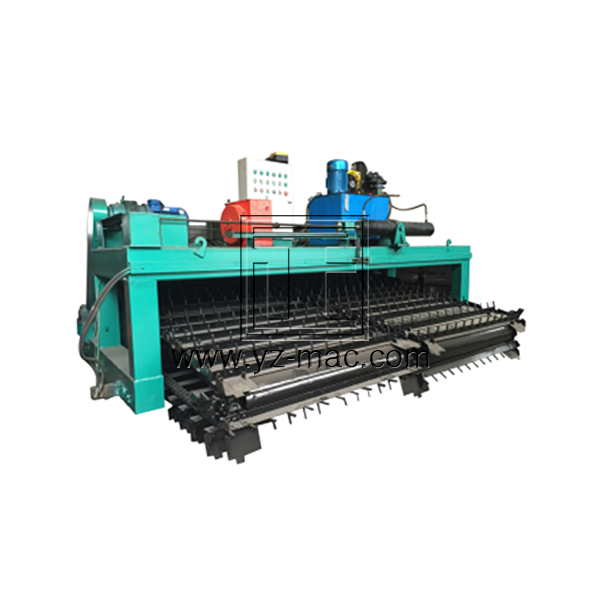

Complete production equipment for organic fertilizer

Pig manure organic fertilizer complete equipment

Condition control of organic fertilizer production is the interaction of physical and biological characteristics in the composting process, and the control conditions are the coordination of the interaction. Wholesale Price China Suger Packaging Machine - Organic Fertilizer Round Polishing Machine – YiZheng , The product will supply to all over the world, such as: Manchester, Istanbul, Mexico, The organic fertilizer granulator is used to granulate various organic substances after fermentation. Before granulation, there is no need to dry and pulverize the raw materials. The spherical granules can be processed directly with ingredients, which can save a lot of energy.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.