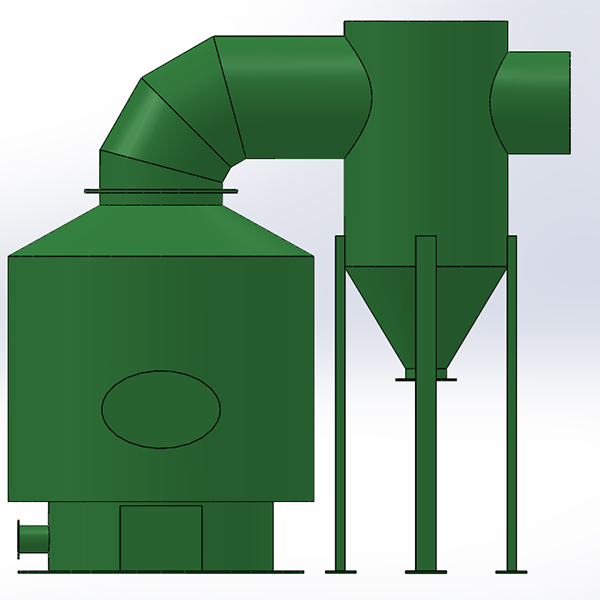

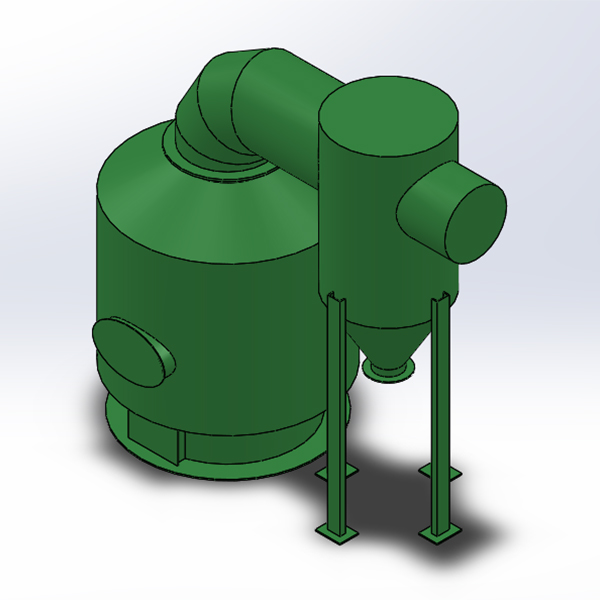

Hot-air Stove

The fuel consumption of Hot-air Stove is about half of using steam or other indirect heaters. Therefore, the direct high-purification hot air can be used without affecting the quality of the dried product.

Fuel can be divided into:

1 Solid fuels, such as coal and coke.

② Liquid fuel, such as diesel, heavy oil, alcohol-based fuel

③ Gas fuel, such as coal gas, natural gas, and liquid gas.

The hot air produced by the fuel combustion reaction contact with the outside air and mix to a certain temperature, and then comes into the drying machine directly, so the mixed hot air full contacts with the fertilizer granules to carry away the moisture. In order to utilize the combustion reaction heat, a whole set of fuel combustion equipment must be worked together, such as: coal burners, oil burners, gas burners, etc.

In the drying process and the wet granulation process, the hot air stove is necessary related equipment, which provides the necessary heat source for the drier system. The series of gas/oil hot air stove has the features of high temperature, low pressure, accurate temperature control and high utilization of heat energy. The air pre-heater is set up in the tail of large hot air stove to improve the efficiency of Hot-air Stove. The convective heating surface adopts a higher reasonable rate on the basis of rigorous calculation to ensure the full heat transfer of the furnace body and the high thermal efficiency of Hot-air Stove.

The test of the Hot-air Stove by the compound fertilizer manufacturer proves that the heating area is large enough and the hot blast volume is sufficient, which greatly reduces the temperature difference between the head and the tail of the rotary single cylinder drying machine, so that the moisture content of the compound fertilizer can be easily controlled within the specified range. The fact proved that the use of Hot-air Stove can not only control the moisture of the granules after drying, but also solve the big problem of fertilizer agglomeration, and at the same time reduce the usage of anti-caking agent to reduce the production cost.

|

Model |

YZRFL-120 |

YZRFL-180 |

YZRFL-240 |

YZRFL-300 |

|

Rated heat supply |

1.4 |

2.1 |

2.8 |

3.5 |

|

Thermal Efficiency(%) |

73 |

73 |

73 |

73 |

|

Coal Consumption (kg/h) |

254 |

381 |

508 |

635 |

|

Power Consumption(kw/h) |

48 |

52 |

60 |

70 |

|

Air supply volume (m3/h) |

48797 |

48797 |

65000 |

68000 |