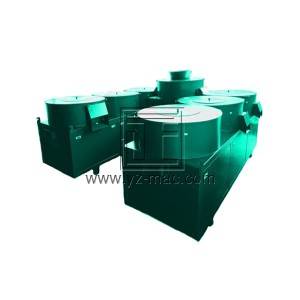

Double Hopper Quantitative Packaging Machine

The Double Hopper Quantitative Packaging Machine is an automatic weighing packing machine suitable for grain, beans, fertilizer, chemical and other industries. For example, packaging granular fertilizer, corn, rice, wheat and granular seeds, medicines, etc. According to your requirements, the rated range of package weight is 5kg ~ 80kg. The quantitative filling and packaging scale machine is mainly composed of four parts: automatic weighing, conveying equipment, bag sealing equipment and computer control. It has the characteristics of reasonable structure, beautiful appearance, stable operation, energy saving and accurate weighing. The main engine adopts dual-frequency spiral propulsion, dual-cylinder measurement, advanced digital frequency conversion control technology, sample processing technology and anti-interference technology to achieve automatic error compensation and correction.

Optional machine material as your demand: Carbon steel, Full stainless steel 304/316L, or Raw material contact parts are stainless steel.

1.Packaging specifications are adjustable, the operation is quite simple under the working condition changes.

2.All parts in contact with materials are made of 304 stainless steel.

3.The total package weight and number of bags accumulated display.

4.Specially designed feeding and measuring, simultaneous bagging and unloading. It saves one-third of the operation time, the package speed is fast, and the packaging precision is high.

5.Using imported sensors, imported pneumatic actuators, reliable work and simple maintenance. The measurement accuracy is plus or minus two thousandths.

6.Wide quantitative range, high precision, with the conveyor sewing machine that can be raised and lowered on the table, one machine is multi-purpose and high efficiency.

|

Model |

Weighing Range (KG) |

Packaging Accuracy |

Packaging Rate |

Microscopic Index Value (kg) |

Working Environment |

||

|

Index |

Per Time |

Average |

Single Weighing |

Temperature |

Relative Humidity |

||

|

YZSBZ-50 |

25-50 |

<±0.2% |

<±0.1% |

300-400 |

0.01 |

-10~40°C |

<95% |

|

Special Model |

≥100 |

Customized processing according to user needs |

|||||

| Remarks | Sewing machine, automatic counting, infrared thread trimming, edge removal machine, you can choose according to customer requirements | ||||||