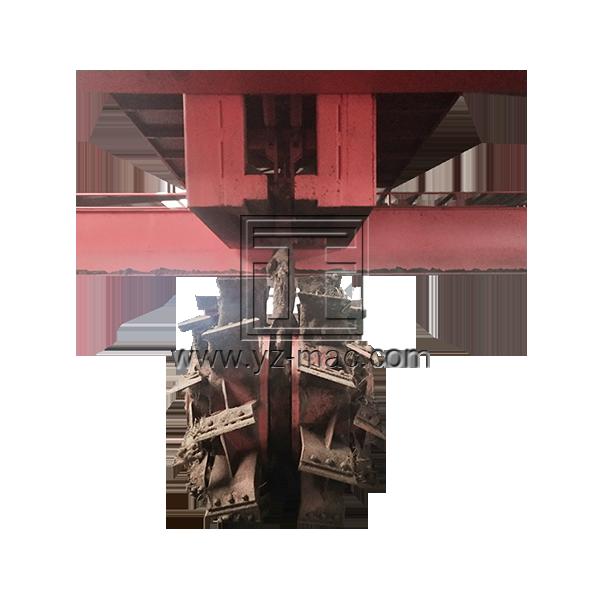

Vertical fertilizer blender

A vertical fertilizer blender, also known as a vertical mixer or vertical blending machine, is a specialized equipment designed for efficient and thorough mixing of various fertilizer materials. By combining different nutrient-rich components, the vertical blender ensures a homogeneous blend, promoting uniform nutrient distribution and maximizing the effectiveness of fertilizers.

Benefits of a Vertical Fertilizer Blender:

Homogeneous Blend: A vertical fertilizer blender ensures a uniform mixture of fertilizer materials. By thoroughly mixing different components, such as nitrogen, phosphorus, potassium, and micronutrients, it creates a balanced and consistent blend. This promotes even distribution of nutrients throughout the fertilizer, increasing its efficiency and effectiveness.

Enhanced Nutrient Availability: The thorough blending achieved by a vertical fertilizer blender maximizes nutrient availability in the final product. The homogeneous blend allows plant roots to access a balanced combination of essential nutrients, promoting healthy plant growth, increased yields, and improved crop quality.

Time and Cost Savings: Utilizing a vertical fertilizer blender streamlines the blending process, reducing manual labor and saving time. It eliminates the need for separate mixing of individual fertilizer components, increasing production efficiency and lowering production costs.

Customizable Formulations: Vertical fertilizer blenders offer flexibility in formulating specific fertilizer blends according to specific crop requirements. They enable precise control over nutrient ratios, allowing customization based on soil nutrient analysis, plant needs, and desired application rates.

Working Principle of a Vertical Fertilizer Blender:

A vertical fertilizer blender consists of a vertical mixing chamber equipped with a rotating shaft and mixing blades. Fertilizer materials are loaded into the chamber, and the blades rotate to lift and tumble the materials, ensuring thorough blending. The vertical design facilitates efficient mixing, as materials are evenly distributed and agitated throughout the blending process. Once the desired blending time is achieved, the well-mixed fertilizer blend is discharged for packaging or further processing.

Applications of Vertical Fertilizer Blenders:

Fertilizer Production Facilities: Vertical fertilizer blenders are extensively used in large-scale fertilizer production facilities. They enable efficient blending of different fertilizer materials, including granules, powders, or micronutrients, to produce high-quality, uniform fertilizers for commercial distribution.

Agricultural Cooperatives: Agricultural cooperatives and farming communities utilize vertical fertilizer blenders to create custom fertilizer blends based on specific soil conditions and crop requirements. The precise control over nutrient ratios ensures optimal fertilization and promotes sustainable agriculture practices.

Garden Centers and Horticultural Operations: Vertical fertilizer blenders are employed in garden centers and horticultural operations to produce specialized blends for various plant species, including flowers, vegetables, and ornamental plants. The ability to customize fertilizer formulations helps meet specific nutrient requirements and achieve optimal plant growth.

Golf Courses and Sports Turf Management: Vertical fertilizer blenders are essential in maintaining healthy turf on golf courses, sports fields, and recreational areas. They enable the creation of precise fertilizer blends that address specific nutrient deficiencies, improving turf quality, color, and overall playability.

A vertical fertilizer blender offers significant advantages in achieving a homogeneous blend and enhancing nutrient distribution in fertilizers. By utilizing this equipment, fertilizer manufacturers, agricultural cooperatives, garden centers, and turf management professionals can create custom blends to meet specific crop or turf requirements. The efficient mixing achieved by a vertical fertilizer blender ensures optimal nutrient availability, resulting in improved plant growth, increased yields, and enhanced crop quality. Whether in large-scale fertilizer production facilities or smaller-scale agricultural operations, the vertical fertilizer blender plays a vital role in optimizing fertilizer formulations and promoting sustainable agriculture practices.