Vertical Fermentation Tank

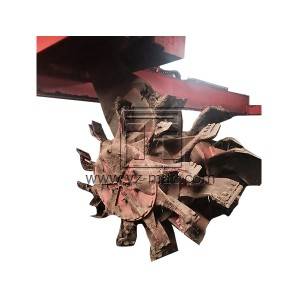

Vertical Waste & Manure Fermentation Tank has the characteristics of short fermentation period, cover small area and friendly environment. The closed aerobic fermentation tank is composed of nine systems: feed system, silo reactor, hydraulic drive system, ventilation system, discharge system, exhaust and deodorization system, panel and electronic control system. Livestock and poultry manure is suggested to add a small amount of excipients like straw and microbial inoculum according to their moisture content and heat value. The feeding system is put into the silo reactor, and the feces are agitated by the impeller blades of the driving mechanism to form a continuous agitation state in the silo. At the same time, the aeration and heat recovery devices of the equipment provide dry hot air for the aeration impeller blades. A uniform hot air space is formed at the back of the blade, which is in full contact with the material for oxygen supply and heat transfer, dehumidification and ventilation. The air is collected and treated from the bottom of the silo through the stack. The temperature in the tank during fermentation can reach 65-83°C, which can ensure the killing of various pathogens. The moisture content of the material after fermentation is about 35%, and the final product is safe and harmless organic fertilizer. The reactor is a closed whole. After the odor is collected through the top pipeline, it is washed and deodorized by water spray and discharged to the standard. It is a new generation of organic fertilizer fermentation tank which is suitable for different regions, based on the similar equipment and through improvement and upgrading. Advanced technology level and favored by the majority of market.

1.The Vertical Waste & Manure Fermentation Tank equipment can be used for the treatment of pig manure, chicken manure, cattle manure, sheep manure, mushroom waste, Chinese medicine waste, crop straw and other organic waste.

2. It only needs 10 hours to complete the harmless treatment process, which has the advantages of covering less (fermentation machine only covers an area of 10-30 square meters).

3. It is the best choice to realize the resource utilization of waste materials for agriculture enterprises, circular agriculture, ecological agriculture.

4. In addition, according to customer requirements, we can customize 50-150m3 different capacity and different forms (horizontal, vertical) of fermentation tank.

5. In the process of fermentation, aeration, temperature controlling, agitation and deodorization can be controlled automatically.

1.On-line CIP cleaning and SIP sterilization (121°C/0.1MPa);

2. According to the requirement of hygiene, the structure design is very humanized and easy to operate.

3. Suitable ratio between diameter and height; according to the need to customize the mixing device, so the energy saving, stirring, the fermentation effect is good.

4. The inner tank has the surface polishing treatment (roughness Ra is less than 0.4 mm). Every outlet, mirror, manhole and so on.

•Vertical design taking a small occupy space

•Close or sealing fermentation, no odor in the air

•Wide application to city/life/food/garden/sewage waste treatment

•Electric heating to transfer oil with cotton thermal insulation

•Inner can be stainless steel plate with thickness 4-8mm

•With insulating layer jacket to improve the composting temperature

•With power cabinet to control the temperature automatically

•Easy use and maintain and can reach self-cleaning

•Paddle mixing shaft can reach complete and full mixing and blending materials