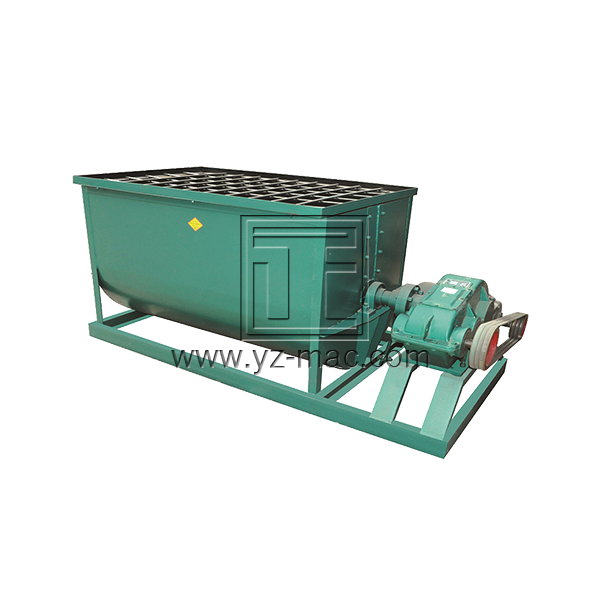

Trending Products Semi-Wet Material Crusher - Chemical Fertilizer Cage Mill Machine – YiZheng

Trending Products Semi-Wet Material Crusher - Chemical Fertilizer Cage Mill Machine – YiZheng Detail:

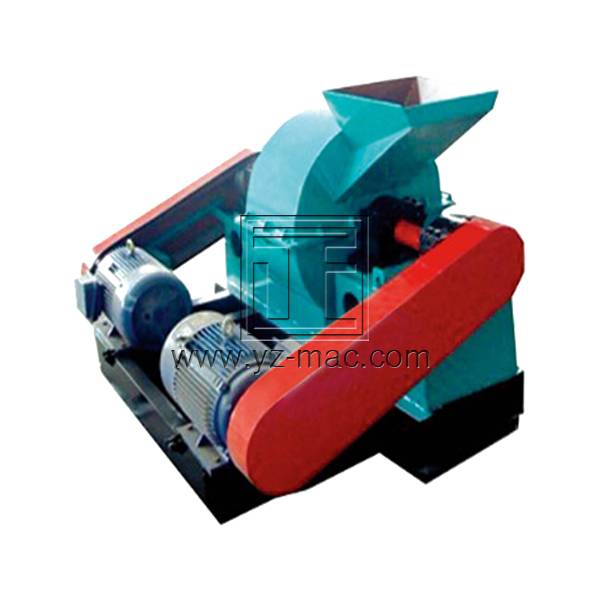

The Chemical Fertilizer Cage Mill Machine belongs to medium-sized horizontal cage mill. This machine is designed according to the principle of impact crushing. When the inside and outside cages rotate in opposite direction with high speed, the material is crushed from inside to outside by the impact of the cage. The cage crusher has the advantages of simple structure, high crushing efficiency, good sealing performance, stable operation, easy cleaning, convenient maintenance and so on.

The Chemical Fertilizer Cage Mill Machine is composed of frame, casing, rat wheel group, mouse wheel group and two electric motors. When working, a motor drives the large cage to rotate smoothly. The other motor drives the small cage to rotate reversely, and the material enters the inner mouse wheel frame through the hopper, the high speed rotating steel bar repeatedly impacts and breaks the material, so as to achieve the fine crushing effect.

(1) This is the one of horizontal cage mill for middle size.

(2) Especially suitable for materials with higher hardness

(3) It has a simple structure and high crushing efficiency

(4) Smooth operation, easy to clean, easy to maintain.

|

Model |

Power(KW) |

Speed (r/min) |

Capacity(t/h) |

Weight (kg) |

|

YZFSLS-600 |

11+15 |

1220 |

4-6 |

2300 |

|

YZFSLS-800 |

15+22 |

1220 |

6-10 |

2550 |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

4. The material should be granulated after stirring evenly. Trending Products Semi-Wet Material Crusher - Chemical Fertilizer Cage Mill Machine – YiZheng , The product will supply to all over the world, such as: Johannesburg, Brasilia, Lithuania, The vermicompost screening machine is mainly used for the separation of finished fertilizer products and returned materials. After screening, the organic fertilizer particles with uniform particle size are transported to the automatic packaging machine through the belt conveyor for weighing and packaging, and the unqualified particles are sent to the crusher. After re-grinding and then re-granulating, the classification of products is realized and the finished products are evenly classified, which is an indispensable equipment in fertilizer production.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!