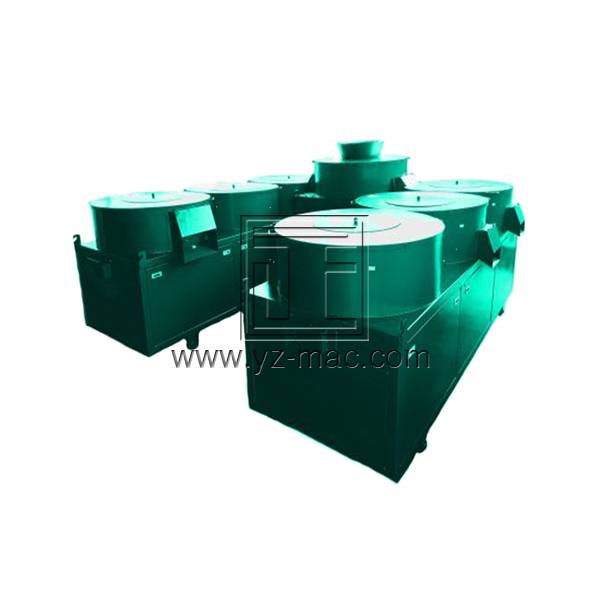

Super Lowest Price Organic Disc Granulator - Rotary Drum Compound Fertilizer Granulator – YiZheng

Super Lowest Price Organic Disc Granulator - Rotary Drum Compound Fertilizer Granulator – YiZheng Detail:

Rotary Drum Compound Fertilizer Granulator is one of the key equipment in the compound fertilizer industry. The main mode of work is spell with wet granulation. Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted in the cylinder after being humidified. In a certain liquid phase, the rotating movement of the barrel is used to make the extrusion pressure of the material into the balls. the whole NPK Compound fertilizer granulation production line includes:

Machine can be divided into five parts:

1) Bracket part: the entire body of the body part of the support by the bracket, the force is greater. Therefore the machine wheeled frame parts are used in the carbon steel plate, welded by the channel, and through a strict quality control and special Process requirements, has reached the purpose of the use of the machine. In addition to the more important is fixed on the shelves of the care, due to take into account its body roll will have a greater friction, I plant specially selected high-quality anti-corrosion, wear-resistant materials, greatly improving the life of the machine, The other is also used in casting one of the four sides of the wheel with a hanging hook, easy loading and unloading transport.

2) Transmission part: the entire granulator drive part is excellent for the whole body of the work have this line. Transmission frame is made of high quality welded steel, and through the strict quality requirements. Install in the transmission frame On the main motor and reducer are selected ISO national exemption products, reliable quality. Motor drives pulley, V-belt, reducer transmission to the spindle, so that the body work, which drive reducer in the spindle part of the work, the use of nylon write off the connector phase bite Transfer drive.

3) Large gear: fixed on the body, and the transmission pinions gear teeth, the opposite drive the body work, the use of high-tech wear-resistant materials, so that the machine longer life.

4) Roller: fixed on both sides of the body to support the entire body.

5) Body part: the whole granulator is the most important part of the body, which is made of high quality carbon steel plate welded, built-in special rubber liner or acid-resistant stainless steel liner, to achieve automatic scars, off the tumor, cancel the traditional scraper device, and through strict quality control and special process requirements to achieve the purpose of the machine used.

1. The granulate rate is up to 70%, only a quite small amount of returns, return product particle size small, can be granulated again.

2. Put into the steam heating, improve the material temperature, the material into the ball after the water is low, improve drying efficiency;

3. with rubber engineering plastics for lining, raw materials is not easy to stick, and play a role in anti-corrosion insulation;

4. Large output, low power consumption, low maintenance cost.

Compound fertilizer was produced by drum granulation. Compound fertilizer can provide nutrients for crops in an all-round way. The method is to chemically produce the main nutrients (such as N, P, K and other trace elements) needed by crops, with nitrogen, phosphorus, potassium and other chemical substances suitable for crop cultivation grain, and then through the application of crops into the soil. Absorb nutrients from the soil. The principle of the process includes nitrogen, phosphorus, potassium particles, ammonium sulfate particles, calcium hydrogen phosphate particles and mixed fertilizer particles: first, phosphorus fertilizer (scientifically known as “calcium superphosphate”) is ammoniated; various powdery raw materials are granulated, dried and cooled to produce finished compound fertilizer. The technological process of compound fertilizer production line can be divided into raw material ingredient, raw material mixing, raw material granulation, particle drying, particle cooling, particle grading, finished product coating and final product packaging.

|

Model |

Cylinder |

Capacity |

Weight |

Motor |

||||

|

Inner diameter |

Length |

Slope Degree

|

Rotary Speed |

Model |

Power |

|||

|

mm |

mm |

(°) |

r/min |

t/h |

t |

Model |

kw |

|

|

YZZLZG-1240 |

1200 |

4000 |

2-5 |

17 |

1-3 |

2.7 |

Y132S-4 |

5.5 |

|

YZZLZG-1450 |

1400 |

5000 |

14 |

3-5 |

8.5 |

Y132M-4 |

7.5 |

|

|

YZZLZG-1660 |

1600 |

6000 |

11.5 |

5-8 |

12 |

Y160M-4 |

11 |

|

|

YZZLZG-1870 |

1800 |

7000 |

11.5 |

8-10 |

18 |

Y160L-4 |

15 |

|

|

YZZLZG-2080 |

2000 |

8000 |

11 |

8-15 |

22 |

Y180M-4 |

18.5 |

|

|

YZZLZG-2280 |

2200 |

8000 |

10.5 |

15-20 |

28 |

Y180L-4 |

22 |

|

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

Production capacity: 12~40 tons/hour; Super Lowest Price Organic Disc Granulator - Rotary Drum Compound Fertilizer Granulator – YiZheng , The product will supply to all over the world, such as: London, Yemen, Sheffield, The fertilizer granulation process is the core part of the organic fertilizer production line. The granulator achieves high-quality and uniform granulation through the continuous process of stirring, collision, inlay, spheroidization, granulation, and densification.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.