First of all, raw chicken manure is not equal to organic fertilizer. Organic fertilizer refers to the straw, cake, livestock manure, mushroom residue and other raw materials through the decomposition, fermentation and processing are made into fertilizer. Animal manure is only one of the raw materials for the production of organic fertilizer.

Whether wet or dry chicken manure is not fermented, it will easily lead to the destruction of greenhouse vegetables, orchards and other cash crops, causing huge economic losses to farmers. Let’s start by looking at the risks of raw chicken manure, and why do people think raw chicken manure is more effective than the other animal manure? And how to make full use of chicken manure correctly and effectively?

Eight disasters easily caused by the use of chicken manure in greenhouses and orchards:

1. Burn roots, burn seedlings and kill plants

After using unfermented chicken manure, if your hand is inserted into the soil, the soil temperature will be significantly higher. In serious cases, the death of flake or full canopy would delay farming and result in the loss of labor cost and seed investment.

In particular, the application of chicken manure in winter and spring has the greatest potential safety hazard, because at this time, the temperature inside the greenhouse is high, and the fermentation of chicken manure will send out a lot of heat, leading to root burning. Chicken manure was used in the orchard in winter and spring, it’s just in the period of root dormancy. Once the root was burned, it would affect nutrient accumulation and flowering and fruiting in the coming year.

2. Salinization of the soil,reduce fruit production

The continuous use of chicken manure has left a large amount of sodium chloride in the soil, with an average of 30-40 kilograms of salt per 6 square meters of chicken manure, and 10 kilograms of salt per acre has seriously restricted soil permeability and activity. Solidified phosphate fertilizer, potash fertilizer, calcium, magnesium, zinc, iron, boron, manganese and other important elements, resulting in abnormal plant growth, sparse flower buds and fruit production, significantly restricting the improvement of crop yield and quality.

As a result, fertilizer utilization rate decreased year by year and input cost increased by 50-100%

3. Acidify soil and induce various rhizosphere diseases and viral diseases

Because the pH of chicken manure is about 4, it is extremely acidic and will acidify the soil, resulting in chemical trauma and severe damage to the stem base and root tissues, providing a large number of viruses carried by chicken manure, soil-borne disease-carrying bacteria, viruses and provides the opportunity for entry and infection, once the humidity and temperature reach the disease will occur.

The use of incomplete fermentation chicken manure, easy to cause plant wilt, yellow withered, atrophy stop growing, no flowers and fruit, and even death; Virus disease, epidemic disease, stalk rot, root rot and bacterial wilt are the most obvious sequelae of chicken manure use.

4.Root knot nematode infestation

Chicken manure is a campsite and breeding ground for root-knot nematodes. The number of root-knot nematode eggs is 100 per 1000 grams. The eggs in chicken manure are easy to hatch and multiply by tens of thousands overnight.

Nematodes are extremely sensitive to chemical agents, and they quickly move to a depth of 50 cm to 1.5 m, making them difficult to cure. Root-knot nematode is one of the most deadly hazards especially for old sheds over 3 years old.

5. Bring in antibiotics, affecting the safety of agricultural products

Chicken feed contains a lot of hormones, and also add antibiotics to prevent disease, these will be carried into the soil through chicken manure, affecting the safety of agricultural products

6. Produce harmful gases, affecting the growth of crops, kill seedlings

Chicken manure in the decomposition process to produce methane, ammonia gas and other harmful gases, so that the soil and crops produce acid damage and root damage, more serious is the production of ethylene gas inhibition of root growth, which is also the main reason for burning roots.

7. Continuous use of chicken feces, resulting in lack of oxygen in the root system

Continuous use of chicken manure results in lack of oxygen in the root system and poor growth. When chicken manure is applied into the soil, it consumes oxygen in the soil during the decomposition process, making the soil temporarily in a state of hypoxia, which will inhibit the growth of crops.

8. Heavy metals exceed the standard

Chicken manure contains high amounts of heavy metals such as copper, mercury, chromium, cadmium, lead and arsenic, as well as many hormone residues, which cause excessive heavy metals in agricultural products, pollute underground water and soil, take a long time for organic matter to transform to humus, and cause serious nutrient loss.

Why does the soil fertility seem particularly high by applying chicken manure?

This is because the chicken’s intestines are straight, excrement and urine together, so the organic matter contained in the chicken manure, more than 60% of the organic matter is in the form of uric acid, uric acid decomposition provides a lot of nitrogen elements, 500 kg of chicken manure is equivalent to 76.5 kg of urea, the surface looks like the crops grow naturally strong. If this kind of circumstance happens in jacket kind or fruit tree grape, it can produce serious physiology disease.

This is mainly because of the antagonism between nitrogen and trace elements and the excessive amount of urea, which will cause the absorption of various middle and trace elements to be blocked, resulting in yellow leaves, umbilical rot, fruit cracking and chicken foot disease.

Have you ever met the situation of burning seedlings or rotting roots in your orchards or vegetable gardens?

Fertilizer is applied a lot, but the yield and quality cannot be improved. Are there any bad cases? such as the death of half the length, soil hardening, heavy stubble, etc. Chicken manure needs to go through fermentation and harmless treatment before it can be applied into the soil!

Rational and effective use of chicken manure

Chicken manure is quite a good raw material of organic fertilizer, which contains about 1.63% pure nitrogen, about 1.54% P2O5 and about 0.085% potassium. It can be processed into organic fertilizer by professional organic fertilizer production equipment. After the fermentation process, harmful insects and weeds seeds will be eliminated with the rise and fall of temperature. The production line of chicken manure basically include fermentation → crushing → mixing of ingredients → granulation → drying → cooling → screening → metering and sealing → storage of finished products.

Flow chart of organic fertilizer production process

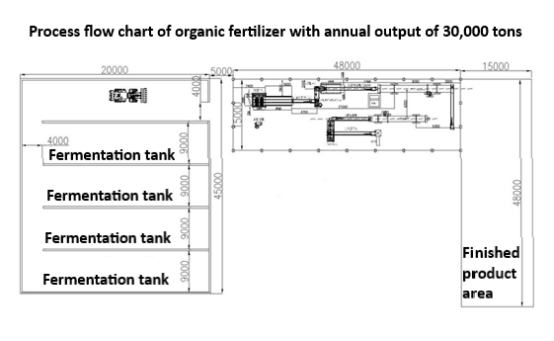

Process flow chart of organic fertilizer with annual output of 30,000 tons

Basic construction of organic fertilizer production line

1. Four fermentation tanks shall be built in the raw material area, each 40m long, 3m wide and 1.2m dee-p, with a total area of 700 square meters;

2. The raw material area shall prepare 320m light rail;

3. The production area covers an area of 1400 square meters;

4. 3 production personnel are required in the raw material area, and 20 personnel are required in the production area;

5. The raw material area needs to buy a three-ton forklift truck.

The main equipment of chicken manure production line:

1. Early-stage fermentation equipment of chicken manure: groove compost turner machine, crawler compost turner machine, self-propelled compost turner machine, chain plate compost turner machine

2. Crushing equipment: semi-wet material crusher, chain crusher, vertical crusher

3. Mixing equipment: horizontal mixer, disc mixer

4. Screening equipment include rotary screening machine and vibrating screening machine

5. Granulator equipment: agitating granulator, disc granulator, extrusion granulator, rotary drum granulator and round-shaping machine

6. Drying equipment: rotary drum dryer

7. Cooling machine equipment: rotary cooling machine

8. Accessory equipment: quantitative feeder, chicken manure dehydrator, coating machine, dust collector, automatic quantitative packaging machine

9. Conveyor equipment: belt conveyor, bucket elevator.

General organic fertilizer production process design includes:

1. Efficient technology of complex strains and bacterial flora proliferation.

2.Advanced material preparation technology and biological fermentation system.

3. The best special fertilizer formula technology (the best combination of product formula can be designed flexibly according to local soil and crop characteristics).

4. Reasonable control technology of secondary pollution (waste gas and odor).

5. Process design and manufacturing technology of fertilizer production line.

Matters needing attention in the production of chicken manure

Fineness of raw materials:

The fineness of raw materials is very important to the production process of organic fertilizer. According to experience, the fineness of the whole raw material should be matched with as follows: 100-60 points of raw material about 30-40%, 60 points to about 1.00 mm in diameter of raw material about 35%, and about 25%-30% in diameter of 1.00-2.00 mm. However, in the process of production, excessive proportion of high fineness materials tend to cause problems such as too large particles and irregular particles due to too good viscosity.

Maturity Standard of Chicken Manure Fermentation

Chicken manure must be fully decomposed before application. The parasites in chicken manure and their eggs, as well as some infectious bacteria, will be inactivated through the process of rotting (fermentation). After fully rotting, chicken manure will become the high-quality basic fertilizer.

1. The Maturity

At the same time with the following three conditions, you can roughly judge the chicken manure has basically fermented.

1. Basically no bad smell; 2. White hyphae; 3. Chicken manure is in a loose state.

The fermenting time is generally about 3 months under natural conditions, which will be greatly accelerated if fermenting agent is added. Depending on the ambient temperature, 20-30 days are generally required, and 7-10 days can be completed under factory production conditions.

2. Humidity

Water content should be adjusted before chicken manure ferments. In the process of fermenting organic fertilizers, the suitability of water content is very important. Because the rotting agent is full of live bacteria, if too dry or too wet will affect the fermentation of microorganisms, generally should be kept at 60 ~ 65%.

Post time: Jun-18-2021