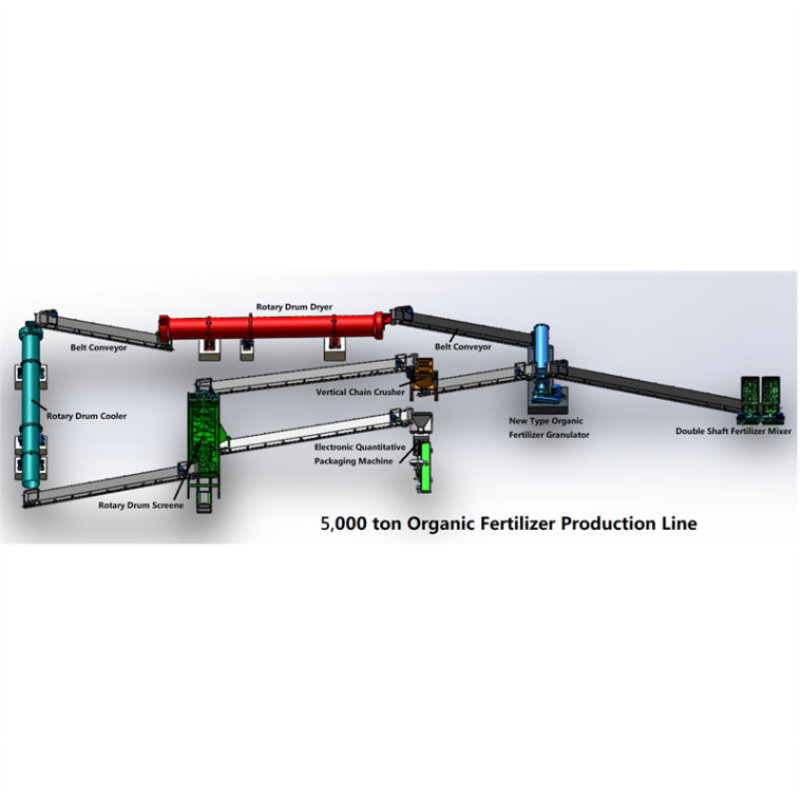

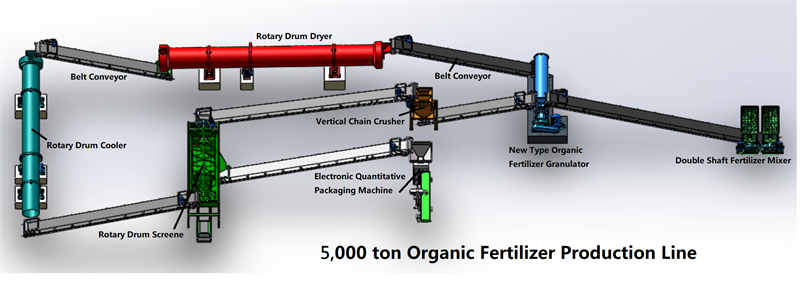

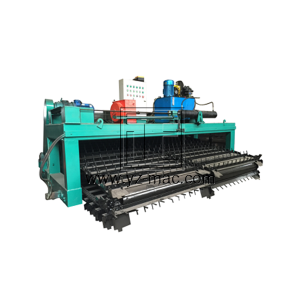

Small-scale bio-organic fertilizer production line

Small bio-organic fertilizer production line.

Yizheng Heavy Industry’s main organic fertilizer production line, a complete set of organic fertilizer equipment, has a large-scale equipment production base of 80,000 square meters, providing dumpers, crushers, granulators, rounding machines, screening machines, dryers, cooling machines, and packaging a full set of fertilizer production line equipment such as machines.

1. Double-axis mixer

The double-axis mixer uses powdered materials such as dry ash and stirred with water to evenly humidify the dry ash powder material, so that the humidified material does not rise dry ashes and does not seep out water droplets, so as to facilitate the transportation of wet ash loading or transfer to other conveying equipment.

|

Model |

Bearing model |

Power |

Shape size |

|

YZJBSZ-80 |

UCP215 |

11KW |

4000×1300×800 |

2. A new organic fertilizer granulator

A new organic fertilizer granulator is used for granulation of chicken dung, pig manure, cow dung, black carbon, clay, kaolin and other particles. The organic content of fertilizer particles can reach 100%. The particle size and uniformity can be adjusted according to the relay speed.

|

Model |

Capacity(t/h) |

Granulation ratio |

Motor power (kW) |

Size L-W – high (mm) |

|

FY-JCZL-60 |

2-3 |

+85% |

37 |

3550×1430×980 |

3. Roller dryer

The roller dryer is used to dry the molded fertilizer particles. The internal lifting plate continuously lifts and throws the molding particles, so that the material is in full contact with the hot air to achieve the purpose of uniform drying.

|

Model |

Diameter (mm) |

Length (mm) |

After installation Shape size (mm) |

Turn speed (r/min) |

Electric motor Model |

Power (kw) |

|

YZHG-0880 |

800 |

8000 |

9000×1700×2400 |

6 |

Y132S-4 |

5.5 |

4. Roller cooler

Roller cooler is a large machine that cools and heats down molded fertilizer particles after drying. While reducing the temperature of molded fertilizer particles, the water content is also reduced. It is a large machine to increase the strength of molded fertilizer particles.

|

Model |

Diameter (mm) |

Length (mm) |

After installation Shape size (mm) |

Turn speed (r/min) |

Electric motor Model |

Power (Kw) |

|

YZLQ-0880 |

800 |

8000 |

9000×1700×2400 |

6 |

Y132S-4 |

5.5 |

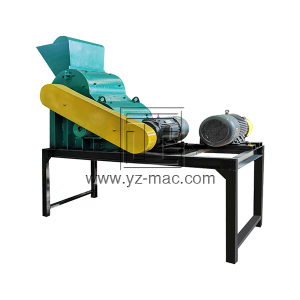

5. Literiform strip grinder

The vertical chain crusher adopts a high-strength amadium-resistant carbide chain with synchronous speed in the grinding process, which is suitable for the grinding of fertilizer production raw materials and refuels.

|

Model |

Maximum particle size of feed (mm) |

After crushing material particle size (mm) |

Motor power(kw) |

Productive capacity(t/h) |

|

YZFSLS-500 |

≤60 |

Φ<0.7 |

11 |

1-3 |

6. Roller sieve

|

Model |

Capacity(t/h) |

Power (kW) |

Inclination(°) |

Size L-W – high (mm) |

|

FY-GTSF-1.2X4 |

2-5 |

5.5 |

2-2.5 |

5000×1600×3000 |

The sieve of the roller sieve machine is used to separate standard fertilizer particles and substandard fertilizer particles.

7. Automatic packaging machine

Use automatic fertilizer packaging machines to wrap organic fertilizer particles by about 2 to 50 kilograms per bag.

|

Model |

Power (kW)) |

Voltage (V) |

Air source consumption(m3/h) |

Air source pressure (MPa) |

Packaging (kg) |

Packaging step bag/meter |

Packaging accuracy |

Overall size L-W-H (mm) |

|

DGS-50F |

1.5 |

380 |

1 |

0.4-0.6 |

5-50 |

3-8 |

±0.2-0.5% |

820×1400×2300 |

Our small organic fertilizer production line provides you with organic fertilizer production process, technology and installation guidelines. For fertilizer investors or farmers, if you have little information about organic fertilizer production, you can start with a small organic fertilizer production line.

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/small-organic-fertilizer-production-lines/