Sheep manure fertilizer coating equipment

Sheep manure fertilizer coating equipment is designed to add a protective coating on the surface of sheep manure pellets to improve their appearance, storage performance, and resistance to moisture and heat. The equipment typically consists of a coating machine, a feeding device, a spraying system, and a heating and drying system.

The coating machine is the main component of the equipment, which is responsible for applying the coating material onto the surface of the sheep manure pellets. The feeding device is used to deliver the pellets to the coating machine, while the spraying system is used to spray the coating material evenly onto the surface of the pellets.

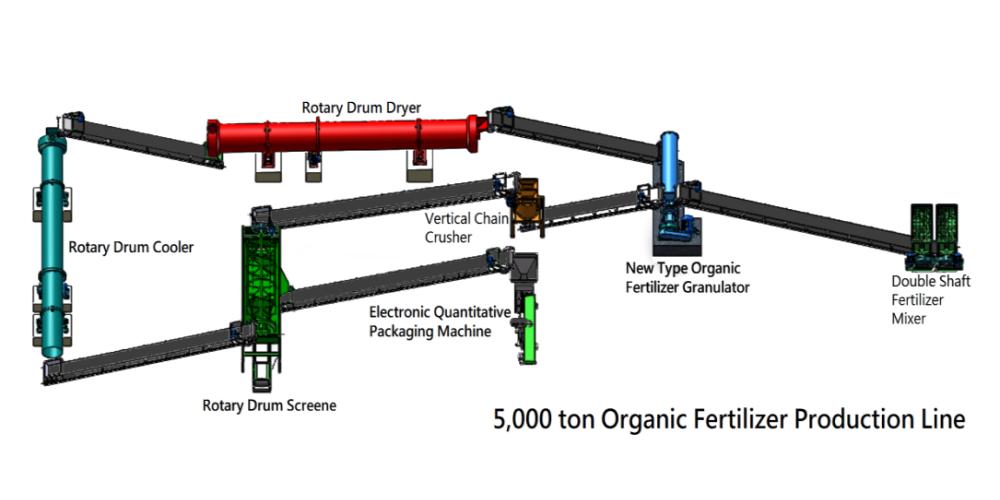

The heating and drying system is used to dry the coated pellets and harden the coating material. The system usually consists of a hot air stove, a rotary drum dryer, and a cooling machine. The hot air stove provides the heat source for the drying process, while the rotary drum dryer is used to dry the pellets. The cooling machine is used to cool down the hot and dried pellets and reduce their temperature to room temperature.

The coating materials used in the sheep manure fertilizer coating equipment can vary depending on the specific requirements of the user. Commonly used materials include wax, resin, sugar, and vegetable oil. These materials can provide a protective layer on the surface of the sheep manure pellets and enhance their appearance, making them more marketable.