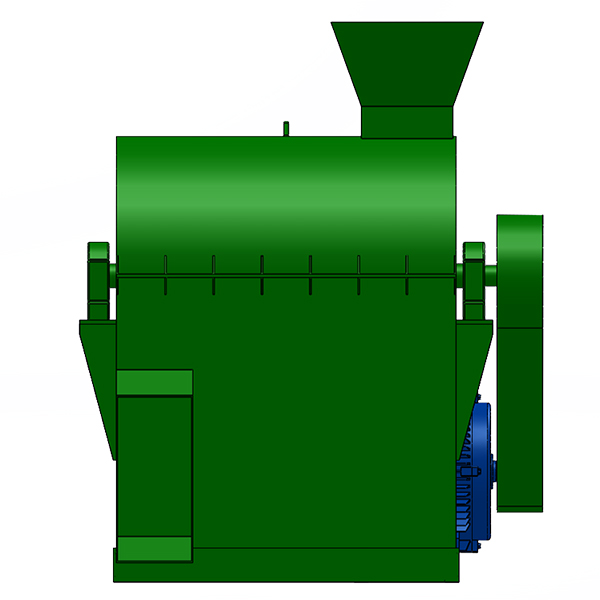

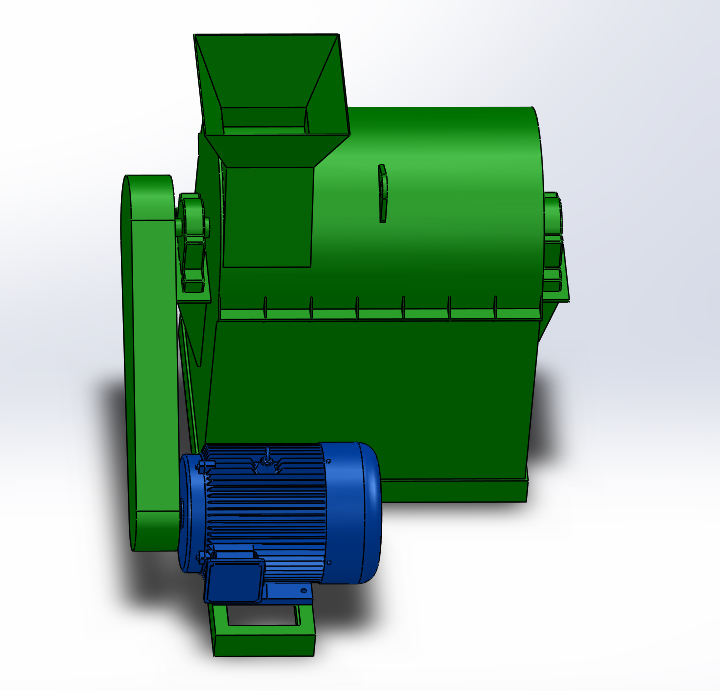

Semi-wet Organic Fertilizer Material Using Crusher

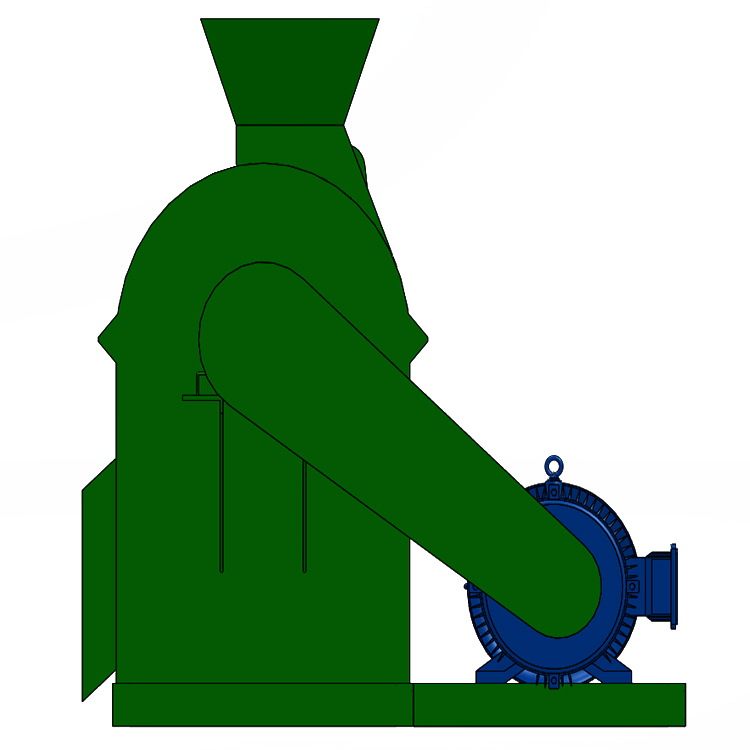

The Semi-wet Material Crushing Machine is a professional crushing equipment for material with high humidity and multi-fiber. The High Moisture Fertilizer Crushing Machine adopts the two-stage rotors, that means it has up and down two-stage crushing. When the raw material is fed through the upper-stage rotor for rough grinding, and then is transported to the lower-stage rotor to continue grind into fine powder to reach the best particle sizes for the next granulating process. There is no sieve mesh at bottom of Semi-wet Material Crushing Machine. So wet materials can be crushed and never blocked. Even materials that have just been taken from the water can be crushed, and no worry about clogged or blocked. The Semi-wet Material Crushing Machine is mostly used in the production and processing of organic fertilizer, it has good effect on raw materials such as chicken manure and humic acid.

Semi-wet Material Crushing Machine is used for crushing biological organic compost fermentation, the urban domestic waste compost fermentation, grass mud carbon, rural garbage, industrial organic waste of straw, breeding livestock and poultry manure and so on.

1.The rotor of the Semi-wet Material Crushing Machine construction adopts rational design & structure. With double-deck blades, its crushing efficiency is twice as much as other crushing machines. The materials enter the crushing part from the feeding hole, then are crushed into fine powder.

2.It adopts high-alloy hard-wearing hammers. The hammer slices are forged to promise they are strong and hard-wearing enough to prolong service life.

3.The rack of this fertilizer grinder is welded by high quality carbon steel plate and box iron. It passes strict production conformity certification & specific technological requirements.

4.The Semi-wet Material Crushing Machine for sale contains two layers of grinding systems to crush the materials finely and attain the optimum efficiency.

5.Adopting flexible belt drive. The electric motor drives the belt sheave which transfers the power to the principal axis, making it rotate in a high speed to crush the materials.

1) Wide application and high reliability. This machine does not have the bottom with screen, so more than 100 kinds of materials can be crushed and the machine will never blocked.

2) Simple maintenance. This machine adopts the two-way gap technology. If the hammer is worn, then the hammer can be used again after moving its position.

3) Good crushing effect. The machine uses the two-stage pulverized rotor, and the material first is crushed into small particles and then crushed into fine dust.

4) Labor saving labor, and the operation is simple. It uses high-tech technology, only one person can operate easily, not only is safe and reliable, but also facilitate maintenance.

|

Model |

YZFSBS-40 |

YZFSBS-60 |

YZFSBS-80 |

YZFSBS-120 |

|

Particle Size (mm) |

0.5—5 |

0.5—5 |

0.5—5 |

0.5—5 |

|

Power (KW) |

22 |

30 |

37 |

75 |

|

Quantity of Short Hammer |

130x50x5=70 pieces |

130x50x5=24 pieces |

180x50x5=32 pieces |

300x50x5=72 pieces |

|

Quantity of Long Hammer |

|

180x50x5=36 pieces |

240x50x5=48 pieces |

350x50x5=48 pieces |

|

Bearing Type |

6212 |

6315 |

6315 |

6318 |

|

Length×width×height |

1040×1150×930 |

1500×1300×1290 |

1700×1520×1650 |

2500×2050×2200 |