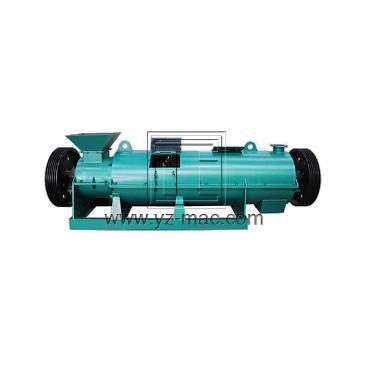

Rotary Drum Granulator

The rotary drum granulator is a specialized machine used in the fertilizer industry to convert powdered materials into granules. With its unique design and operation, this granulation equipment offers several advantages, including improved nutrient distribution, enhanced product consistency, and increased production efficiency.

Benefits of the Rotary Drum Granulator:

Enhanced Nutrient Distribution: The rotary drum granulator ensures even distribution of nutrients within each granule. This is achieved through the tumbling action of the drum, which allows the powdered materials to adhere and form granules with consistent nutrient content. The uniform nutrient distribution promotes balanced fertilization and improved crop growth.

Improved Product Consistency: The rotary drum granulator produces uniform-sized granules with consistent composition. This ensures that each granule contains a balanced combination of nutrients, resulting in consistent application and nutrient release. The uniformity of the granules simplifies handling, transportation, and storage, providing convenience for farmers and fertilizer manufacturers.

Increased Production Efficiency: The rotary drum granulator offers high production capacity, making it suitable for large-scale fertilizer production. Its continuous operation, coupled with efficient material mixing and granulation, allows for a streamlined production process. This results in higher productivity, reduced production costs, and improved overall efficiency.

Working Principle of the Rotary Drum Granulator:

The rotary drum granulator consists of a rotating drum, an inclined support frame, and a drive system. The powdered materials, along with a liquid binder or solution, are fed into the rotating drum. As the drum rotates, the materials tumble and collide, resulting in the formation of granules. The wetting agent or binder helps bind the particles together, creating spherical granules. The size and shape of the granules can be adjusted by controlling the drum speed and inclination.

Applications of the Rotary Drum Granulator:

Fertilizer Production: The rotary drum granulator is widely used in the production of compound fertilizers, including NPK (nitrogen, phosphorus, and potassium) fertilizers. It is particularly suitable for granulating materials with varying nutrient ratios, ensuring balanced nutrient distribution in each granule.

Agriculture and Horticulture: The granules produced by the rotary drum granulator are ideal for agricultural and horticultural applications. They provide a convenient and efficient way to deliver nutrients to crops, promoting optimal growth and improving yield and quality. The controlled-release nature of the granules ensures a steady supply of nutrients over an extended period.

Environmental Remediation: The rotary drum granulator is also utilized in environmental remediation projects. It can be used to granulate materials for soil amendment and land reclamation. By converting waste materials into granules, the rotary drum granulator helps reduce waste volume and facilitates the application of beneficial materials to improve soil fertility and restore degraded land.

The rotary drum granulator offers significant benefits in the production of granular fertilizers, providing enhanced nutrient distribution, improved product consistency, and increased production efficiency. Its unique design and operation enable the creation of uniform-sized granules with balanced nutrient content. The granules produced by the rotary drum granulator find applications in agriculture, horticulture, and environmental remediation. By utilizing this efficient granulation equipment, fertilizer manufacturers can enhance their production processes, optimize nutrient delivery to crops, and contribute to sustainable agriculture practices.