PriceList for Compost Turning Equipment - Horizontal Fermentation Tank – YiZheng

PriceList for Compost Turning Equipment - Horizontal Fermentation Tank – YiZheng Detail:

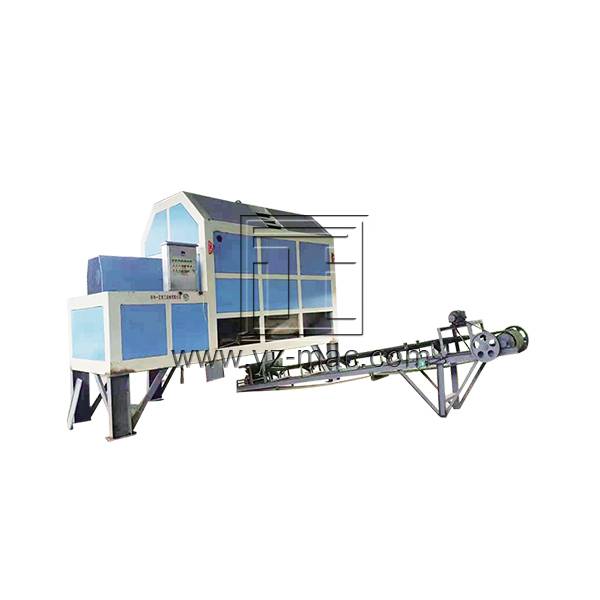

High Temperature Waste & Manure Fermentation Mixing Tank mainly carry out high-temperature aerobic fermentation of livestock and poultry manure, kitchen waste, sludge and other waste by using the activity of microorganisms to achieve integrated sludge treatment which is harmless, stable, reduced and resourced.

First, put the materials to be fermented into the Waste & Manure Fermentation Mixing Tank from the feed port through the belt conveyor. While putting the materials, start the main motor, and the motor speed reducer drives the main shaft to start mixing. At the same time, the spiral blades on the stirring shaft turn the animal materials over, so that the materials are in full contact with the air, so that the materials to be fermented start to undergo aerobic fermentation.

Secondly, the heating system of the electric heating rod at the bottom is controlled by the electric box to start heating the heat transfer oil in the interlayer of the fermenter body. While heating, the temperature of the fermenter body is controlled by the temperature sensor to control the temperature of the fermenter at the fermentation station. The required state. After the fermentation of the material is completed, the material is discharged out of the tank for the next step.

The structure of Waste & Manure Fermentation Mixing Tank can be divided into:

1. Feeding system

2. Tank fermentation system

3. Power mixing system

4. Discharging system

5. Heating and heat preservation system

6. Maintenance part

7. Fully automatic electrical control system

(1) The equipment is small in size, can be installed outdoors, and does not require a factory building. It is a mobile processing factory, which solves the high cost problem of plant building, long-distance transportation and centralized processing;

(2) Sealed treatment, deodorization 99%, without pollution;

(3) Good thermal insulation, not limited by the cold season, can be fermented normally in the environment below minus 20 degrees Celsius;

(4) Good mechanical material, solve the problem of strong acid and alkali corrosion, long service life;

(5) Simple operation and management, input raw materials such as animal manure, automatically produce organic fertilizer, easy to learn and operate;

(6) The fermentation cycle is about 24-48 hours, and the processing capacity can be increased according to needs.

(7) Low energy consumption, greatly reducing the cost of producing electricity;

(8) Aerobic species can survive and reproduce at -25 ℃-80 ℃. The beneficial bacteria formed can kill harmful bacteria in raw materials. This feature makes other organic fertilizers incomparable and beyond.

|

Specification model |

YZFJWS-10T |

YZFJWS-20T |

YZFJWS-30T |

|

Device size (L*W*H) |

3.5m*2.4m*2.9m |

5.5m*2.6m*3.3m |

6m*2.9m*3.5m |

|

Capacity |

>10m³ (water capacity) |

>20m³ (water capacity) |

>30m³ (water capacity) |

|

Power |

5.5kw |

11kw |

15kw |

|

Heating System |

Electric heating |

||

|

Aeration System |

Air compressor aeration equipment |

||

|

Control System |

One set of automated control systems |

||

Product detail pictures:

Related Product Guide:

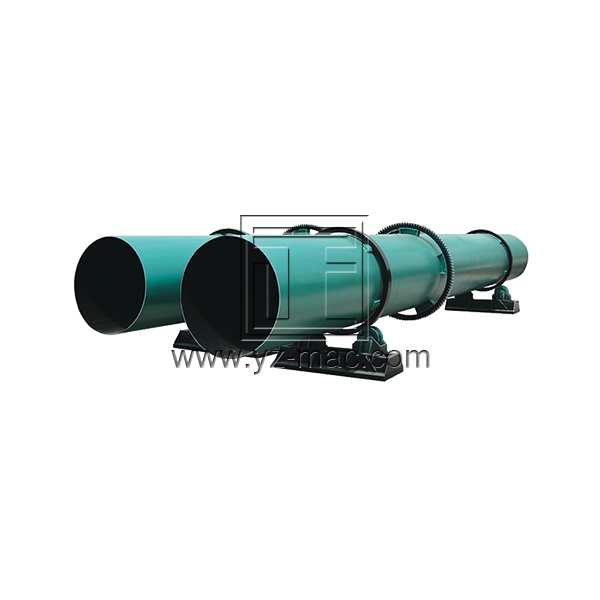

Compound fertilizer production process

Pig manure organic fertilizer complete equipment

7. The screening machine needs to screen out the unqualified particles of fertilizer, and the unqualified materials will also be returned to the production line for qualified treatment and reprocessing. PriceList for Compost Turning Equipment - Horizontal Fermentation Tank – YiZheng , The product will supply to all over the world, such as: Canberra, Ecuador, Lesotho, The composting screening machine classifies and screens various materials, and the particles after screening are uniform in size and high in screening accuracy. The compost screening machine has the advantages of stability and reliability, low consumption, low noise and high screening efficiency.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!