Powdery organic fertilizer production equipment

Powdery organic fertilizer production equipment is used to produce powdery organic fertilizer from organic materials such as animal manure, crop straw, and kitchen waste. The basic equipment that may be included in this set are:

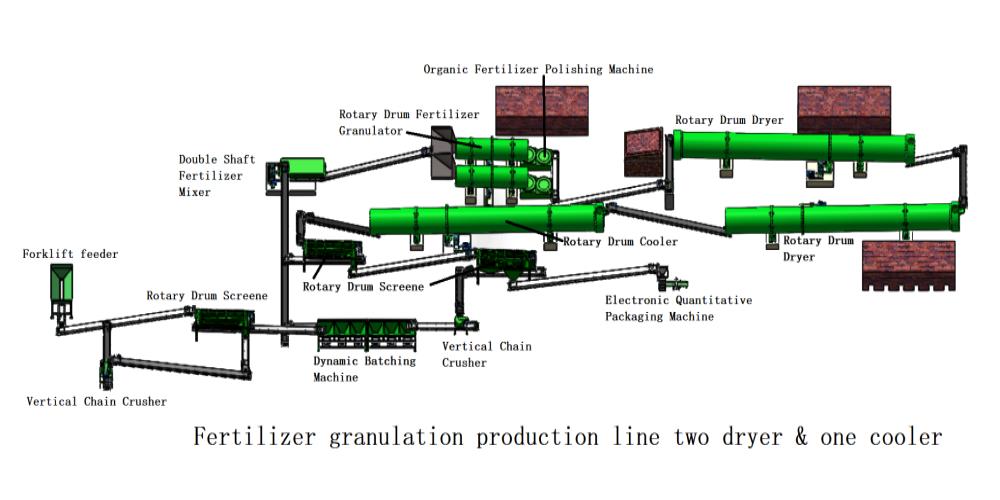

1.Crushing and Mixing Equipment: This equipment is used to break down the raw materials and mix them together to create a balanced fertilizer mixture. It can include a crusher, a mixer, and a conveyor.

2.Screening Equipment: This equipment is used to screen and grade the mixed materials to separate out large particles and impurities. Screening equipment can include a vibrating screen or a rotary screener.

3.Drying Equipment: This equipment is used to dry the screened materials to a moisture content suitable for grinding and granulation. Drying equipment can include a rotary dryer or a fluid bed dryer.

4.Grinding Equipment: This equipment is used to grind the dried materials into a fine powder. Grinding equipment can include a hammer mill or a roller mill.

5.Packaging Equipment: This equipment is used to pack the powdery organic fertilizer into bags or other containers. Packaging equipment can include a bagging machine or a bulk packing machine.

6.Conveyor System: This equipment is used to transport the raw materials and finished products between different processing equipment.

7.Control System: This equipment is used to control the operation of the entire production process and ensure the quality of the organic fertilizer products.

It is important to note that the specific equipment needed may vary depending on the type of organic material being processed, as well as the specific requirements of the production process. Additionally, automation and customization of the equipment may also impact the final list of required equipment.