Other

-

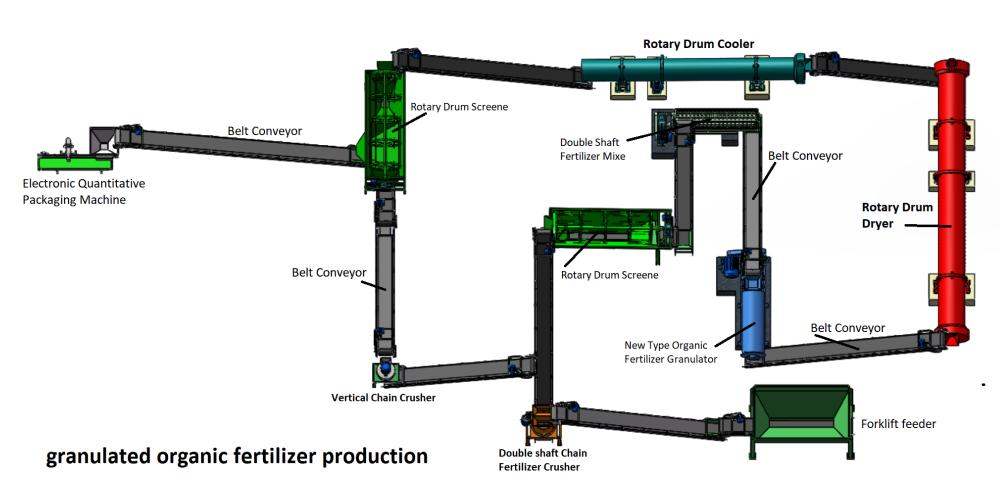

Granular organic fertilizer production line

A granular organic fertilizer production line is a type of organic fertilizer production process that produces organic fertilizer in the form of granules. This type of production line typically includes a series of equipment, such as a compost turner, crusher, mixer, granulator, dryer, cooler, and packaging machine. The process begins with the collection of organic raw materials, such as animal manure, crop residues, and food waste. The materials are then processed into a fine powder using a ... -

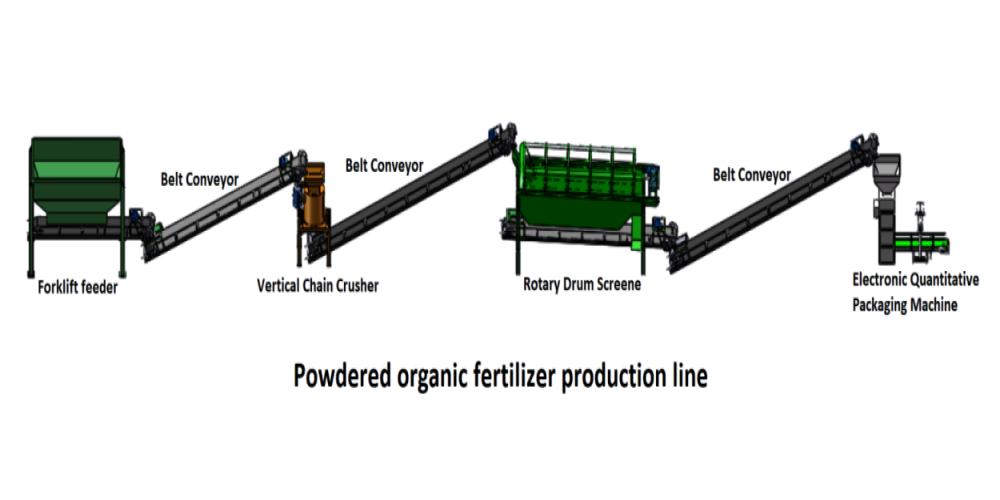

Powdery organic fertilizer production line

A powdery organic fertilizer production line is a type of organic fertilizer production line that produces organic fertilizer in the form of a fine powder. This type of production line typically includes a series of equipment, such as a compost turner, crusher, mixer, and packing machine. The process begins with the collection of organic raw materials, such as animal manure, crop residues, and food waste. The materials are then processed into a fine powder using a crusher or grinder. The powd... -

Livestock manure organic fertilizer production line

A livestock manure organic fertilizer production line is a type of organic fertilizer production line that uses livestock manure as the main raw material to produce organic fertilizer products. The production line typically includes a series of equipment, such as a compost turner, crusher, mixer, granulator, dryer, cooler, screener, and packing machine. The process starts with the collection of raw materials, which in this case is livestock manure. The manure is then composted to create a sta... -

Disc granulator production line

A disc granulator production line is a type of fertilizer production line that uses a disc granulator machine to produce granular fertilizer products. The disc granulator is a kind of equipment that creates granules by rotating a large disc, which has a number of inclined and adjustable angle pans attached to it. The pans on the disc rotate and move the material to create granules. The disc granulator production line typically includes a series of equipment, such as a compost turner, crusher,... -

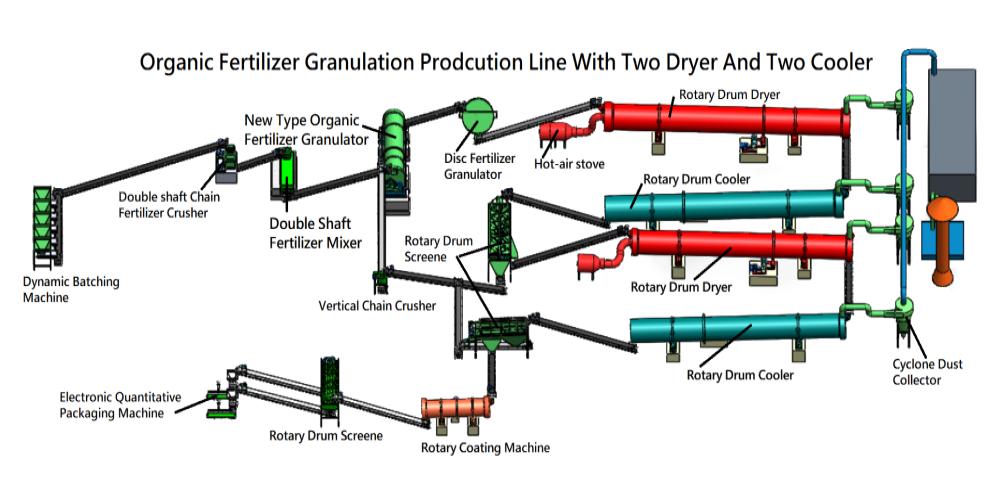

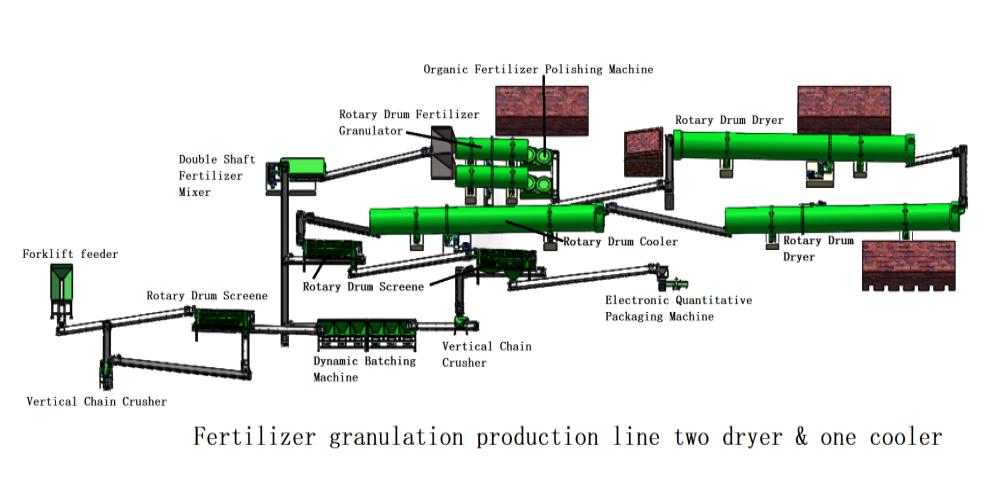

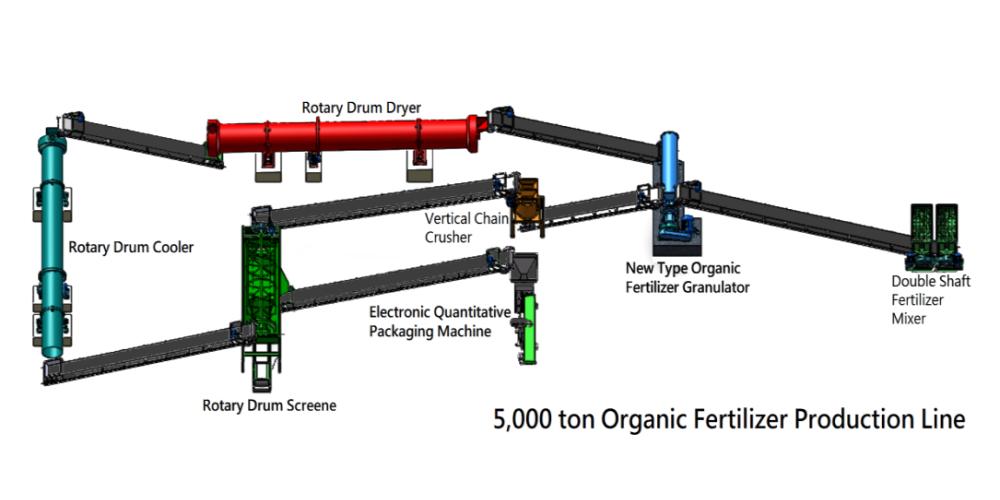

Organic fertilizer granulation production line

An organic fertilizer granulation production line is a set of equipment used to convert organic waste materials into granular fertilizer products. The production line typically includes a series of machines such as compost turner, crusher, mixer, granulator, dryer, cooler, screening machine, and packing machine. The process starts with the collection of organic waste materials, which may include animal manure, crop residue, food waste, and sewage sludge. The waste is then turned into compost ... -

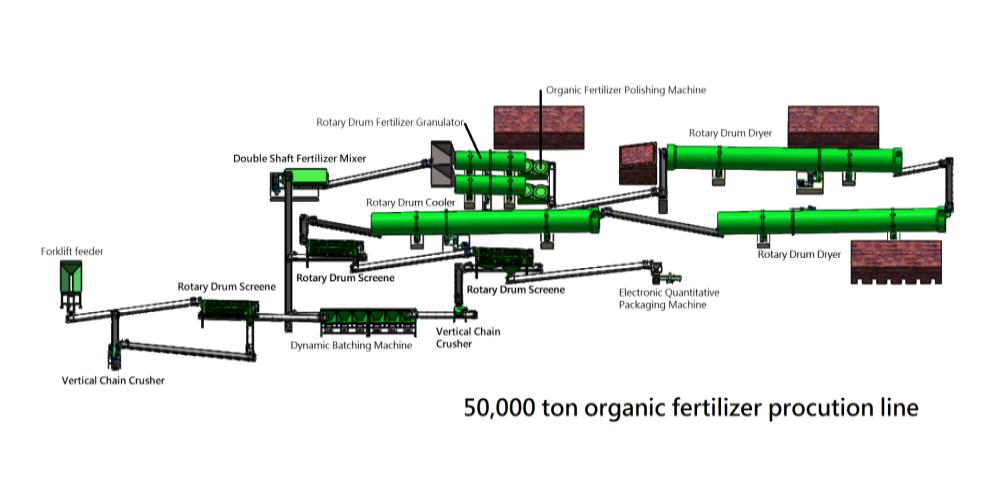

Organic fertilizer production line with an annual output of 50,000 tons

An organic fertilizer production line with an annual output of 50,000 tons typically includes the following steps: 1.Raw Material Preprocessing: Raw materials such as animal manure, crop residues, food waste, and other organic waste materials are collected and preprocessed to ensure their suitability for use in organic fertilizer production. 2.Composting: The preprocessed raw materials are mixed and placed in a composting area where they undergo natural decomposition. This process can take se... -

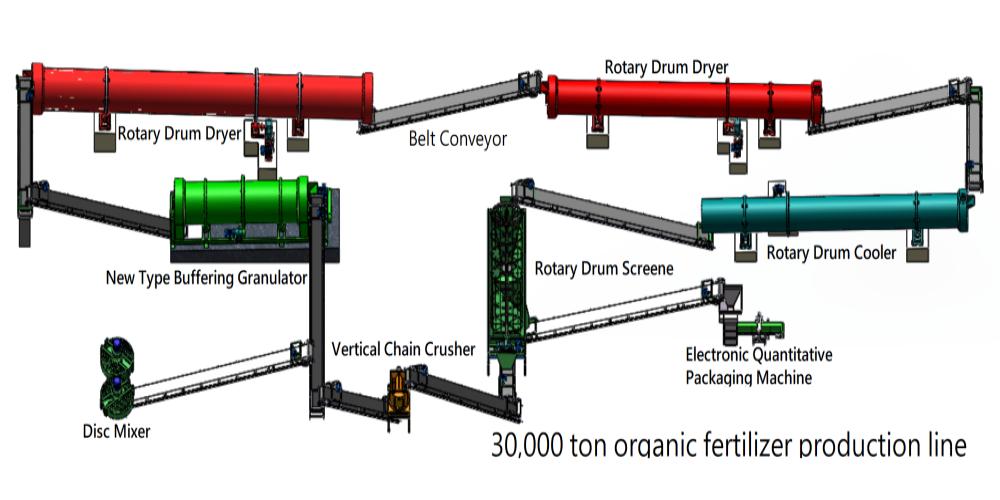

Organic fertilizer production line with an annual output of 30,000 tons

An organic fertilizer production line with an annual output of 30,000 tons typically includes the following steps: 1.Raw Material Preprocessing: Raw materials such as animal manure, crop residues, food waste, and other organic waste materials are collected and preprocessed to ensure their suitability for use in organic fertilizer production. 2.Composting: The preprocessed raw materials are mixed and placed in a composting area where they undergo natural decomposition. This process can take se... -

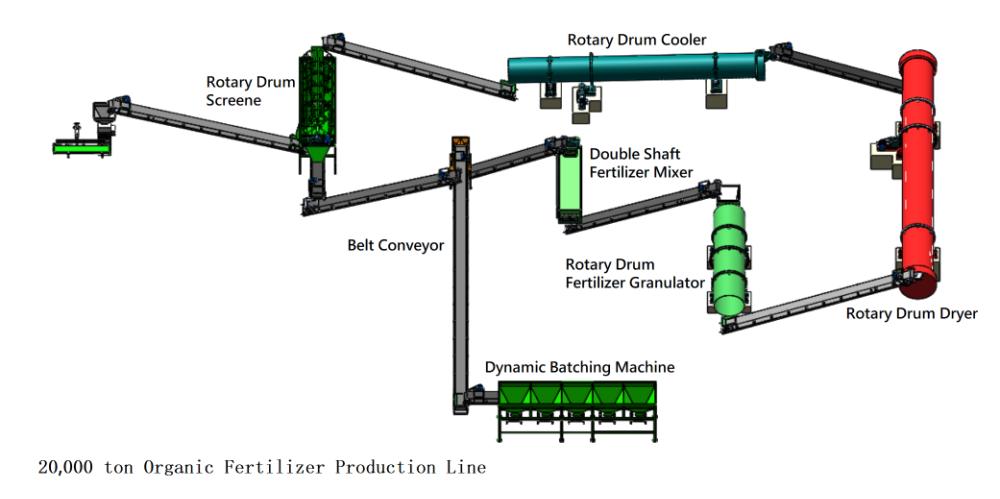

Organic fertilizer production line with an annual output of 20,000 tons

An organic fertilizer production line with an annual output of 20,000 tons typically includes the following steps: 1.Raw Material Preprocessing: This involves collecting and preprocessing the raw materials to ensure they are suitable for use in the production of organic fertilizer. Raw materials may include animal manure, crop residues, food waste, and other organic waste materials. 2.Composting: The raw materials are then mixed together and placed in a composting area where they are left to ... -

No drying extrusion granulation production line

A no-drying extrusion granulation production line is a process for producing granulated fertilizer without the need for a drying process. This process uses a combination of extrusion and granulation technologies to create high-quality fertilizer granules. Here is a general outline of a no-drying extrusion granulation production line: 1.Raw Material Handling: The first step is to collect and handle the raw materials. The raw materials used in the production of granulated fertilizer can include... -

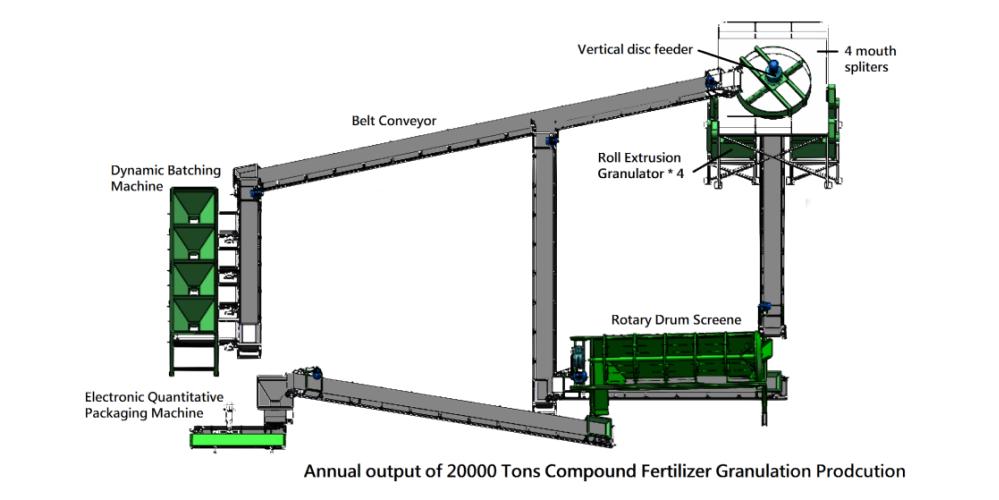

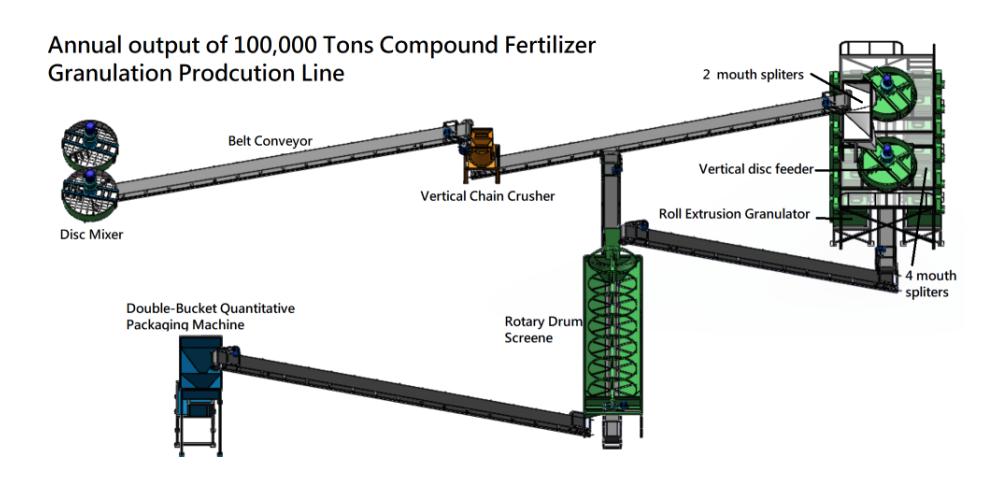

No drying extrusion compound fertilizer production line

A no-drying extrusion compound fertilizer production line is a type of production line that produces compound fertilizer without the need for a drying process. This process is known as extrusion granulation and is an innovative and efficient method of producing compound fertilizers. Here is a general outline of a no-drying extrusion compound fertilizer production line: 1.Raw Material Handling: The first step is to collect and handle the raw materials. The raw materials used in the production ... -

Small-scale bio-organic fertilizer production line

A small-scale bio-organic fertilizer production line can be an efficient way for small-scale farmers or gardeners to produce high-quality organic fertilizer using organic waste materials. Here is a general outline of a small-scale bio-organic fertilizer production line: 1.Raw Material Handling: The first step is to collect and handle the raw materials, which can be a variety of organic waste materials such as crop residue, animal manure, food waste, or green waste. The organic waste materials... -

Small-scale earthworm manure organic fertilizer production line

A small-scale earthworm manure organic fertilizer production line can be an efficient way for small-scale farmers or gardeners to produce high-quality organic fertilizer. Here is a general outline of a small-scale earthworm manure organic fertilizer production line: 1.Raw Material Handling: The first step is to collect and handle the raw materials, which in this case is earthworm manure. The manure is collected and stored in a container or pit before being processed. 2.Vermicomposting: The ea...