Other

-

Promote fermentation and maturity by using a flipper

Promoting Fermentation and Decomposition by Turning Machine During the composting process, the heap should be turned if necessary. Generally, it is carried out when the heap temperature crosses the peak and begins to cool down. The heap turner can re-mix the materials with different decomposition temperatures of the inner layer and the outer layer. If the humidity is insufficient, some water can be added to promote the compost to decompose evenly. The fermentation process of organic compost i... -

Compost fermentation technology

Fermentation of organic fertilizer is mainly divided into three stages The first stage is the exothermic stage, during which a lot of heat is generated. The second stage enters the high temperature stage, and as the temperature rises, the heat-loving microorganisms become active. The third is to start the cooling stage, at this time the organic matter is basically decomposed. -

Core elements of compost maturity

Organic fertilizer can improve the soil environment, promote the growth of beneficial microorganisms, improve the quality and quality of agricultural products, and promote the healthy growth of crops. Condition control of organic fertilizer production is the interaction of physical and biological characteristics in the composting process, and the control conditions are the coordination of the interaction. Moisture Control – During the manure composting process, the relative moisture con... -

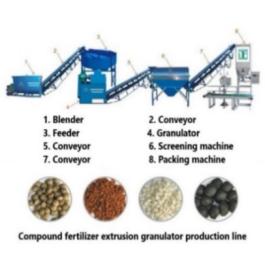

Compound fertilizer production line

Compound fertilizer is a compound fertilizer that is mixed and batched according to different proportions of a single fertilizer, and a compound fertilizer containing two or more elements of nitrogen, phosphorus and potassium is synthesized through chemical reaction, and its nutrient content is uniform and the particle size is consistent. The raw materials for compound fertilizer production include urea, ammonium chloride, ammonium sulfate, liquid ammonia, monoammonium phosphate, diammonium p... -

NPK compound fertilizer production line

NPK compound fertilizer production line NPK compound fertilizer is a compound fertilizer that is mixed and batched according to different proportions of a single fertilizer, and a compound fertilizer containing two or more elements of nitrogen, phosphorus and potassium is synthesized by chemical reaction, and its nutrient content is uniform and the particle size is consistent. The compound fertilizer production line has a wide range of adaptability to the granulation of various compound ferti... -

Fertilizer production line

BB fertilizer production line. It is suitable for the production of BB fertilizers prepared by mixing elemental nitrogen, phosphorus, potassium granular fertilizers with other medium and trace elements, pesticides, etc. in a certain proportion. The equipment is flexible in design and can meet the needs of various large, medium and small fertilizer production enterprises. main feature: 1. Using microcomputer batching, high batching accuracy, fast batching speed, and can print reports and query... -

Organic fertilizer production line

The organic fertilizer production line is to convert various organic wastes into organic fertilizers through different processes. The organic fertilizer factory can not only turn various livestock and poultry manure, kitchen waste, etc. generate environmental benefits. Organic fertilizer production line equipment mainly includes: 1. Fermentation equipment: trough type turner, crawler type turner, chain plate type turner. 2. Pulverizer equipment: semi-wet material pulverizer, vertical pulveriz... -

The production process of organic fertilizer you want to know

The production process of organic fertilizer is mainly composed of: fermentation process – crushing process – stirring process – granulation process – drying process – screening process – packaging process, etc. 1. First, the raw materials such as livestock manure should be fermented and decomposed. 2. Secondly, the fermented raw materials should be fed into the pulverizer by the pulverizing equipment to pulverize the bulk materials. 3. Add appropriate ingr... -

Fertilizer crusher

Organic fertilizer crushing equipment, fertilizer crushing equipment, is widely used in the production process of organic fertilizer, and has a good crushing effect on wet raw materials such as chicken manure and sludge. -

Compost shredder

Compost crusher is widely used in organic fermentation, organic waste, chicken manure, cow manure, sheep manure, pig manure, duck manure and other special equipment for the crushing process of biological fermentation high-humidity materials -

Compost crusher machine

The organic fertilizer pulverizer is used for the pulverization operation after bio-organic composting, and the pulverization degree can be adjusted within the range according to the needs of the user. -

Compost shredder chipper

The fermented compost raw materials enter the pulverizer to pulverize the bulk materials into small pieces that can meet the granulation requirements.