Other

-

Graphite granulation process equipment

Graphite granulation process equipment refers to the machinery and equipment used in the process of granulating graphite material. This equipment is designed to transform graphite into granules or pellets of desired size and shape. The specific equipment used in the graphite granulation process may vary depending on the desired final product and the production scale. Some common types of graphite granulation process equipment include: 1. Ball mills: Ball mills are commonly used to grind and p... -

Graphite granulation production line

A graphite granulation production line refers to a complete set of equipment and processes designed for the production of graphite granules. It involves the transformation of graphite powder or a graphite mixture into granular form through various techniques and steps. The production line typically includes the following components: 1. Graphite Mixing: The process begins with the mixing of graphite powder with binders or other additives. This step ensures homogeneity and uniform distribution ... -

Graphite pellet forming machine

A graphite pellet forming machine is a specific type of equipment used for shaping graphite into pellet form. It is designed to apply pressure and create compacted graphite pellets with a consistent size and shape. The machine typically follows a process that involves feeding graphite powder or a graphite mixture into a die or mold cavity and then applying pressure to form the pellets. Here are some key features and components commonly associated with a graphite pellet forming machine: 1. Die... -

Graphite compactor

A graphite compactor, also known as a graphite briquetting machine or graphite compacting press, is a specific type of equipment used to compress graphite powder or graphite fines into compact and dense briquettes or compacts. The compaction process helps improve the handling, transportation, and storage properties of graphite materials. Graphite compactors typically involve the following components and mechanisms: 1. Hydraulic system: The compactor is equipped with a hydraulic system that ge... -

Graphite granulation equipment

Graphite granulation equipment refers to the machinery and devices specifically designed for the process of granulating or pelletizing graphite materials. This equipment is used to transform graphite powder or a graphite mixture into well-formed and uniform graphite granules or pellets. Some common types of graphite granulation equipment include: 1. Pellet mills: These machines use pressure and a die to compress graphite powder or a graphite mixture into compacted pellets of desired size and ... -

Graphite pelletizer

Graphite pelletizer refers to a device or machine used specifically for pelletizing or forming graphite into solid pellets or granules. It is designed to process graphite material and transform it into a desired pellet shape, size, and density. The graphite pelletizer applies pressure or other mechanical forces to compact the graphite particles together, resulting in the formation of cohesive pellets. The graphite pelletizer can vary in design and operation depending on the specific requireme... -

Graphite extruder

A graphite extruder is a type of equipment used in the production of graphite products, including graphite pellets. It is specifically designed to extrude or force the graphite material through a die to create the desired shape and form. The graphite extruder typically consists of a feeding system, an extrusion barrel, a screw or ram mechanism, and a die. The graphite material, often in the form of a mixture or blend with binders and additives, is fed into the extrusion barrel. The screw or r... -

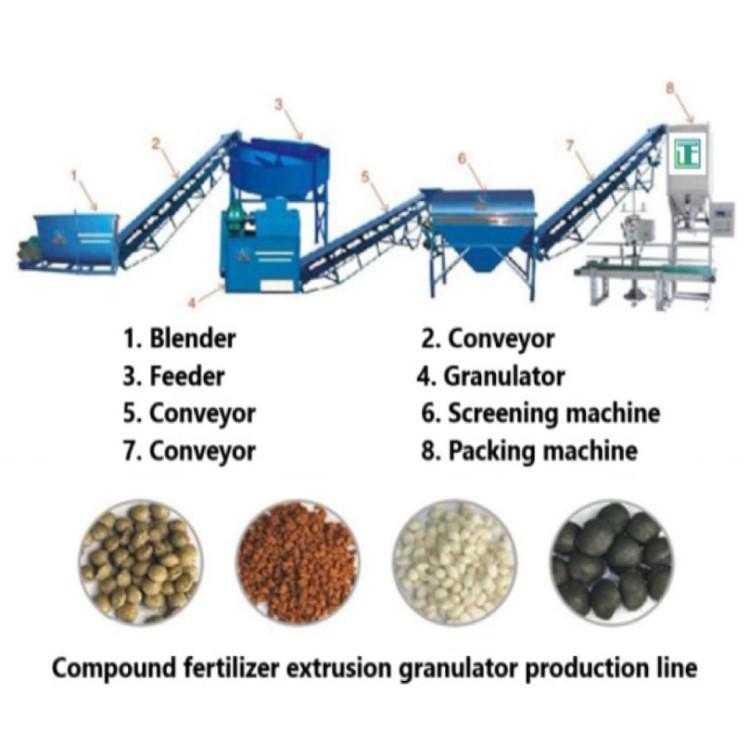

Double roller extrusion granulator

It is a type of granulation equipment commonly used in the production of compound fertilizers. The double roller extrusion granulator works by squeezing materials between two counter-rotating rollers, which causes the materials to form into compact, uniform granules. The granulator is particularly useful for processing materials that are difficult to granulate using other methods, such as ammonium sulfate, ammonium chloride, and NPK fertilizers. The final product has high quality and is easy ... -

Vermicomposting equipment

Earthworms are nature’s scavengers. They can convert food waste into high nutrients and various enzymes, which can promote the decomposition of organic matter, make it easier for plants to absorb, and have adsorption effects on nitrogen, phosphorus and potassium, so it can promote plant growth. Vermicompost contains high levels of beneficial microorganisms. Therefore, the use of vermicompost can not only maintain the organic matter in the soil, but also ensure that the soil will not be ... -

Vermicomposting machine

To make vermicompost by composting machine, vigorously promote the application of vermicompost in agricultural production, and promote the sustainable and circular development of agricultural economy. Earthworms feed on the animal and plant debris in the soil, turn the soil loose to form earthworm pores, and at the same time it can decompose the organic waste in human production and life, turning it into inorganic matter for plants and other fertilizers. -

Vermicompost making machine

Vermicompost composting mainly involves worms digesting a large amount of organic waste, such as agricultural waste, industrial waste, livestock manure, organic waste, kitchen waste, etc., which can be digested and decomposed by earthworms and converted into vermicompost compost for use as organic fertilizer. Vermicompost can combine organic matter and microorganisms, promote clay loosening, sand coagulation and soil air circulation, improve soil quality, promote the formation of soil aggrega... -

Vermicompost machinery

Vermicomposting is through the action of earthworms and microorganisms, the waste is transformed into odorless and with lower harmful compounds, higher plant nutrients, microbial biomass, soil enzymes, and things similar to humus. Most earthworms can digest their own body weight of organic waste per day and multiply rapidly, so earthworms can provide a faster and less expensive solution to environmental problems.