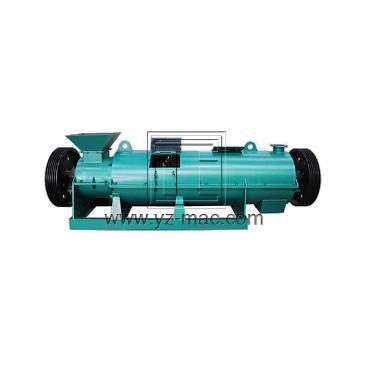

Organic manure making machine

An organic manure making machine is a revolutionary equipment designed to convert organic waste into high-quality, nutrient-rich fertilizer.

Benefits of an Organic Manure Making Machine:

Waste Recycling: An organic manure making machine allows for the effective recycling of organic waste, including animal manure, crop residues, kitchen scraps, and agricultural by-products. By converting this waste into organic fertilizer, it mitigates environmental pollution and reduces reliance on chemical-based fertilizers.

Nutrient-Rich Fertilizer Production: The organic manure making machine processes organic waste through a controlled decomposition process, resulting in nutrient-rich fertilizer. This fertilizer is abundant in essential nutrients like nitrogen (N), phosphorus (P), potassium (K), as well as other micronutrients required for plant growth and soil health.

Improved Soil Health: Organic fertilizers produced by the manure making machine enhance soil fertility and structure. They promote beneficial microbial activity, improve soil water retention, and provide a gradual release of nutrients, fostering a healthy and productive soil ecosystem.

Sustainable Agriculture: The use of organic fertilizers supports sustainable agricultural practices. They reduce the risk of chemical runoff and contamination of water bodies, protect beneficial organisms, and contribute to long-term soil health and fertility.

Working Principle of an Organic Manure Making Machine:

An organic manure making machine employs a bioconversion process called composting or fermentation. The machine creates an ideal environment for the decomposition of organic waste by controlling factors such as temperature, moisture, and oxygen levels. During the composting process, microorganisms break down the waste materials, converting them into nutrient-rich organic fertilizer.

Applications of an Organic Manure Making Machine:

Agriculture and Horticulture: Organic manure produced by the machine is widely used in agriculture and horticulture for crop production. It enriches the soil with essential nutrients, improves soil structure, enhances plant growth and development, and increases crop yields.

Organic Farming: The organic manure making machine supports organic farming practices by providing a reliable source of nutrient-rich organic fertilizers. Organic farmers can utilize the machine to process organic waste on-site, ensuring a continuous supply of organic fertilizer for their crops.

Landscaping and Gardening: Organic fertilizer produced by the machine is ideal for landscaping and gardening applications. It promotes healthy growth of plants, enhances soil fertility, and reduces the need for synthetic fertilizers, creating sustainable and eco-friendly landscapes.

Soil Remediation and Land Reclamation: The organic manure making machine plays a crucial role in soil remediation and land reclamation projects. The nutrient-rich organic fertilizer helps restore degraded soils, improves soil structure, and supports the establishment of vegetation in previously barren or contaminated areas.

An organic manure making machine offers a sustainable and efficient solution for converting organic waste into nutrient-rich organic fertilizer. By recycling organic waste and producing high-quality fertilizer, it contributes to waste reduction, improved soil health, and sustainable agricultural practices.