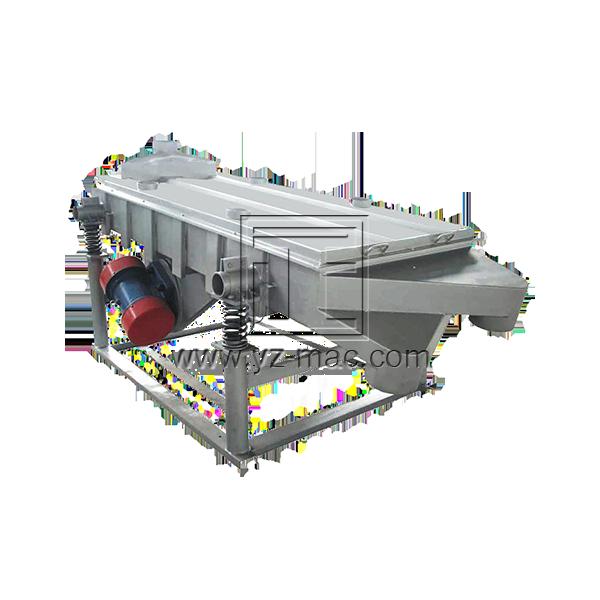

Organic Fertilizer Vibrating Sieving Machine

Send email to us

Previous:

Organic Fertilizer Screening Machine

Next:

Organic Fertilizer Rotary Vibration Sieving Machine

Organic fertilizer vibrating sieving machine is a type of equipment used in the production of organic fertilizer. The machine is designed to separate the finished fertilizer products from the larger particles and impurities. The vibrating sieving machine uses a vibrating motor to vibrate the screen, which separates the fertilizer particles based on their size. The smaller particles fall through the screen while the larger particles are transported to the crusher or granulator for further processing. The vibrating sieving machine is an important equipment in the production of organic fertilizer as it helps to ensure the quality and consistency of the final product.

Write your message here and send it to us