Organic fertilizer production process

The organic fertilizer production process typically involves several stages, including:

1.Collection of organic waste: This includes collecting organic waste materials such as agricultural waste, animal manure, food waste, and municipal solid waste.

2.Pre-treatment: The collected organic waste materials are pre-treated to prepare them for the fermentation process. Pre-treatment can include shredding, grinding, or chopping the waste to reduce its size and make it easier to handle.

3.Fermentation: The pre-treated organic waste is then fermented to break down the organic matter and create a nutrient-rich compost. This can be done using a variety of techniques, including windrow composting, static pile composting, or vermicomposting.

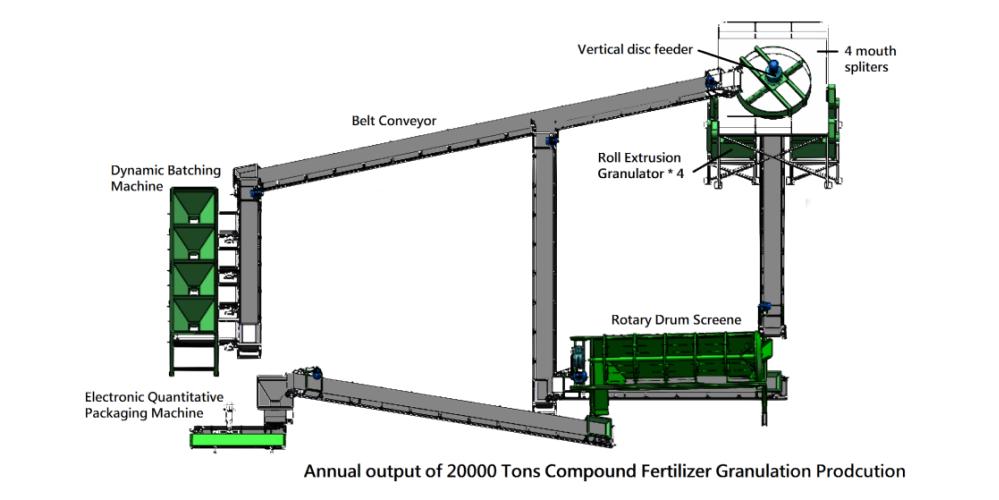

4.Mixing and crushing: Once the compost is ready, it is mixed with other organic materials such as minerals or other organic sources, and then crushed to create a uniform mixture.

5.Granulation: The mixture is then processed through a granulator or pellet mill, which forms it into small, uniform pellets or granules.

6.Drying and cooling: The pellets or granules are then dried using a dryer or dehydrator, and cooled to ensure that they are stable and free from moisture.

7.Screening and packing: The final stage involves screening the finished product to remove any undersized or oversized particles, and then packing the organic fertilizer into bags or other containers for storage and distribution.

It is important to ensure proper maintenance and operation of the equipment used in the organic fertilizer production process to ensure efficiency and successful production of high-quality organic fertilizers. Additionally, organic fertilizers can vary in their nutrient content, so it is important to conduct regular testing and analysis of the finished product to ensure that it meets the desired specifications.