Organic Fertilizer Production Process

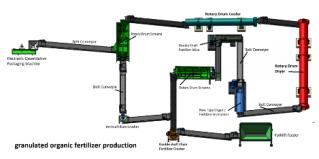

The organic fertilizer production process typically involves the following steps:

1.Collection of raw materials: Organic materials, such as animal manure, crop residues, and food waste, are collected and transported to the fertilizer production facility.

2.Pre-treatment: The raw materials are screened to remove any large contaminants, such as rocks and plastics, and then crushed or ground into smaller pieces to facilitate the composting process.

3.Composting: The organic materials are placed in a composting pile or vessel and allowed to decompose over several weeks or months. During this process, microorganisms break down the organic materials and produce heat, which helps to kill off pathogens and weed seeds. Composting can be carried out using different methods, such as aerobic composting, anaerobic composting, and vermicomposting.

4.Fermentation: The composted materials are then further fermented to enhance the nutrient content and reduce any remaining odors. This can be done using different fermentation methods, such as aerobic fermentation and anaerobic fermentation.

5.Granulation: The fermented materials are then granulated or pelletized to make them easier to handle and apply. This is typically done using a granulator or pelletizer machine.

6.Drying: The granulated materials are then dried to remove any excess moisture, which can cause clumping or spoilage. This can be done using different drying methods, such as sun drying, natural air drying, or mechanical drying.

7.Screening and grading: The dried granules are then screened to remove any oversize or undersize particles, and graded to separate them into different sizes.

8.Packaging and storage: The final product is then packaged into bags or other containers, and stored in a dry, cool place until it is ready for use.

The specific organic fertilizer production process may vary depending on the type of organic materials used, the desired nutrient content and quality of the final product, and the available equipment and resources. It is important to follow proper hygiene and safety practices throughout the production process to ensure the quality and safety of the final product.