Organic fertilizer production machine

An organic fertilizer production machine is a vital tool in the process of converting organic waste materials into nutrient-rich fertilizers. These machines play a crucial role in sustainable agriculture by promoting the recycling of organic resources, reducing reliance on synthetic fertilizers, and improving soil health.

Significance of Organic Fertilizer Production Machines:

Nutrient Recycling: Organic fertilizer production machines allow for the recycling of organic waste materials, such as animal manure, crop residues, food waste, and green waste. By processing these materials, valuable nutrients are transformed into organic fertilizers, reducing waste and closing the nutrient cycle.

Soil Enrichment: Organic fertilizers produced by these machines provide essential nutrients to the soil, promoting soil fertility and structure. They enhance soil microbial activity, improve nutrient availability, increase organic matter content, and contribute to the overall health of the soil ecosystem.

Environmentally Friendly: Organic fertilizer production machines support sustainable agricultural practices by reducing the dependence on synthetic fertilizers. Organic fertilizers are derived from natural sources and do not contribute to the pollution of waterways or the accumulation of harmful chemicals in the soil.

Working Principles of Organic Fertilizer Production Machines:

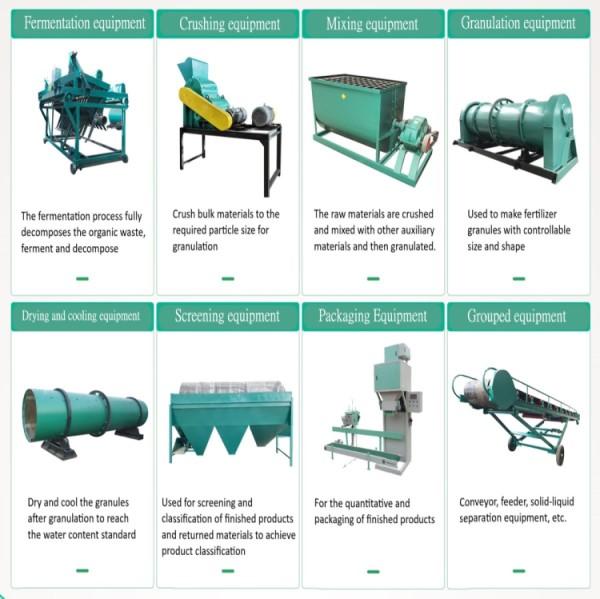

Fermentation: The process begins with the collection of organic waste materials, which are then subjected to a fermentation process. Microorganisms, such as bacteria and fungi, break down the organic matter, converting it into a nutrient-rich mixture.

Composting: The fermented organic matter is then transferred to composting systems, where it undergoes decomposition under controlled conditions. Composting promotes the breakdown of complex organic compounds, converting them into stable organic matter that is rich in nutrients.

Crushing and Mixing: Once the composting process is complete, the organic matter is crushed and mixed to achieve a homogeneous blend. This ensures the uniform distribution of nutrients throughout the organic fertilizer product.

Granulation and Drying: The crushed and mixed organic matter is then transformed into granules through a granulation process. This enhances the convenience of handling, storage, and application of the organic fertilizer. The granules are then dried to achieve the desired moisture content.

Applications of Organic Fertilizer Production Machines:

Organic Farming: Organic fertilizer production machines are extensively used in organic farming to supply essential nutrients to crops and enhance soil fertility. These machines provide farmers with a sustainable and eco-friendly approach to nourishing their plants and maintaining soil health.

Gardening and Landscaping: Organic fertilizers produced by these machines are ideal for gardening and landscaping applications. They enrich the soil, promote healthy plant growth, and minimize the use of synthetic chemicals, ensuring safe and sustainable cultivation practices.

Horticulture and Nursery Operations: Organic fertilizer production machines support horticultural and nursery operations by providing nutrient-rich fertilizers for the production of healthy and vibrant plants. These machines enable the customization of fertilizer blends to suit specific plant requirements, fostering optimal growth and development.

Sustainable Waste Management: Organic fertilizer production machines contribute to sustainable waste management by processing organic waste materials and converting them into valuable fertilizers. This reduces the amount of waste sent to landfills and transforms it into a resource that enriches the soil and promotes a circular economy.

Organic fertilizer production machines are vital in the transformation of organic waste materials into nutrient-rich fertilizers. They enable the recycling of valuable nutrients, enhance soil fertility, and promote sustainable agricultural practices. By using these machines, farmers, gardeners, and horticulturists can harness the power of organic resources, reduce dependence on synthetic fertilizers, and contribute to a more sustainable and environmentally friendly approach to farming and gardening.