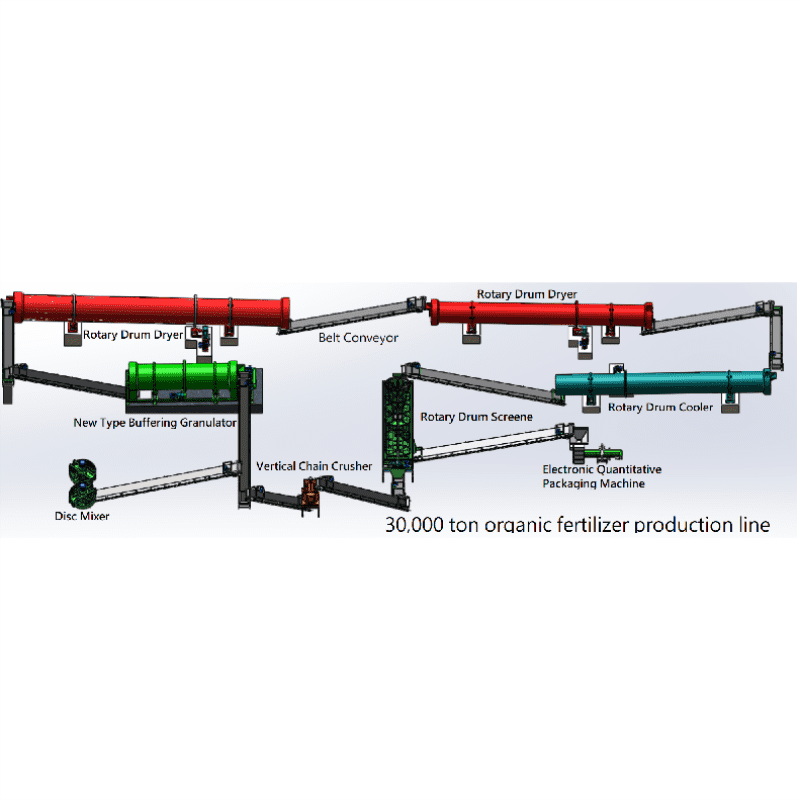

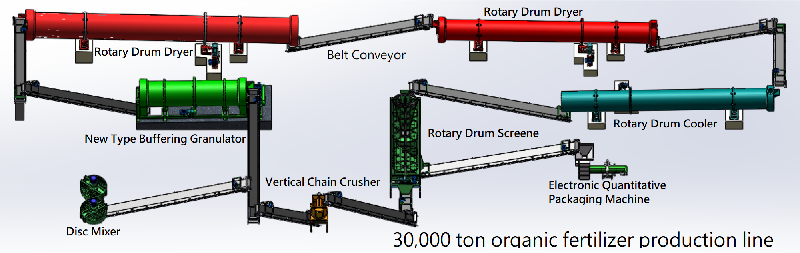

Organic fertilizer production line with an annual output of 30,000 tons.

The 30,000-ton organic fertilizer production line converts various organic wastes into organic fertilizer through different processes. The bio-organic fertilizer plant can not only turn chicken manure, kitchen waste, etc. into treasure, produce economic benefits, but also reduce environmental pollution and produce environmental benefits. The particle shape can be cylindrical or spherical, which is convenient for transportation and use. The equipment can be selected according to your actual needs.

Work Principle :

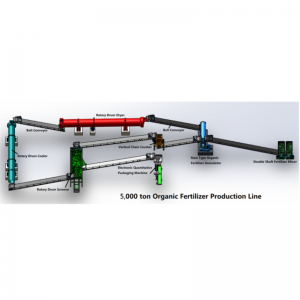

The process includes fermentation equipment, mixer, granulation machine, dryer, cooler, roller sieve machine, silo, fully automatic packaging machine, vertical crusher, belt conveyor, etc.

1. Drum dumper

The fermentation process fully decomposes the organic waste into fermentation and ripening. Different plugs such as walking dumpers, double-helix dumpers, grooved plugs, groove hydraulic dumpers and tracked dumpers produced by our company can be selected according to actual composting raw materials, venues and products.

2. Crushing machine

The fermented raw material enters the vertical chain grinder, which can crush raw materials with a water content of less than 30%. The particle size can reach 20-30 orders, which meets the granulation requirements.

3. Horizontal mixer

After crushing, add the auxiliary material according to the formula and mix evenly in the blender. Horizontal mixer has two options: a uniaxial mixer and a double-axis mixer.

4. A new organic fertilizer granulator

The qualified granulation rate of the machine is as high as 90%, which is suitable for a variety of different formulas. The compressive strength of the particles is higher than that of disk granulation and drum granulation, and the large spherical rate is less than 15%.

5. Round thrower

The rounding machine can repair and beauty the granulation particles after granulation. After extruding granulation or disk granulation process, after throwing rounding, the fertilizer particles can be uniform in size, accurate roundness, bright and smooth on the surface, large particle strength, and the spherical yield of fertilizer is as high as 98%.

6. Dry and cool

The roller dryer continuously pumps the heat source in the hot air stove at the nose position to the tail of the engine through the fan installed at the tail of the machine, so that the material is in full contact with the hot air and reduce the water content of the particles.

The roller cooler cools particles at a certain temperature after drying, and reduces the water content of particles again while reducing the particle temperature.

7. Roller sieve

It is mainly used for separating finished products from recycled materials. After sieving, qualified particles are fed into the coating machine, and unqualified particles are fed into the vertical chain crusher to regrainate, thus achieving product classification and uniform classification of finished products. The machine adopts a combined screen, which is easy to maintain and replace. Its structure is simple, easy to operate and smooth. Steady, it’s an indispensable equipment in fertilizer production.

8. Packaging machine:

The coating of qualified particles through a rotary coating machine not only makes the particles beautiful, but also improves the hardness of the particles. The rotary coating machine adopts special liquid material spraying technology and solid powder spraying technology to effectively prevent fertilizer particle blocking.

9. Automatic packaging machine:

After the particles are coated, they are packaged by the packaging machine. The packaging machine has a high degree of automation, integrating weighing, suture, packaging and transportation, which realizes rapid quantitative packaging and makes the packaging process more efficient and accurate.

10. Belt conveyor:

The conveyor plays an indispensable role in the production process, because it connects different parts of the entire production line. On this compound fertilizer production line, we choose to provide you with a belt conveyor. Compared with other types of conveyors, belt conveyors have large coverage, making your production process more efficient and economical.

Yizheng Heavy Industry is a professional manufacturer of organic fertilizer equipment. Our products have complete specifications and good quality! The products are well made and delivered in time. Welcome to call and buy.

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/30000-ton-organic-fertilizer-production-lines/