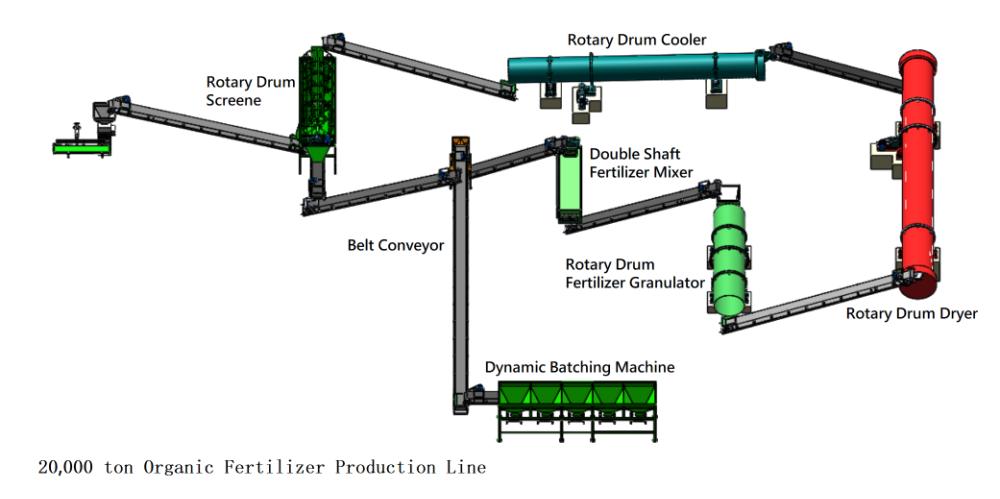

Organic fertilizer production line with an annual output of 20,000 tons

An organic fertilizer production line with an annual output of 20,000 tons typically includes the following steps:

1.Raw Material Preprocessing: This involves collecting and preprocessing the raw materials to ensure they are suitable for use in the production of organic fertilizer. Raw materials may include animal manure, crop residues, food waste, and other organic waste materials.

2.Composting: The raw materials are then mixed together and placed in a composting area where they are left to decompose. The decomposition process can take several weeks to several months, depending on the type of raw materials used.

3.Crushing and Mixing: After the composting process is complete, the decomposed materials are crushed and mixed together to create a homogeneous mixture. This is typically done using a crusher and a mixing machine.

4.Granulation: The mixed materials are then fed into a granulator machine, which compresses the materials into small pellets or granules. The size and shape of the granules can be adjusted to meet specific customer requirements.

5.Drying: The newly formed granules are then dried using a dryer machine to remove any excess moisture. This helps to increase the shelf life of the fertilizer.

6.Cooling and Screening: The dried granules are then cooled and screened to remove any oversized or undersized particles, ensuring a consistent product.

7.Coating and Packaging: The final step is to coat the granules with a protective layer and package them into bags or other containers for distribution.

To produce 20,000 tons of organic fertilizer annually, a production line would require a significant amount of equipment and machinery, including crushers, mixers, granulators, dryers, cooling and screening machines, and packaging equipment. The specific equipment and machinery needed would depend on the type of raw materials being used and the desired characteristics of the final product. Additionally, skilled labor and expertise would be required to operate the production line effectively and efficiently.