Organic fertilizer production line

Organic fertilizer production line refers to the entire process of making organic fertilizer from raw materials. It typically involves several steps including composting, crushing, mixing, granulating, drying, cooling, and packaging.

The first step is to compost organic materials such as manure, crop residues, and food waste to create a nutrient-rich substrate for plant growth. The composting process is facilitated by microorganisms, which break down the organic matter and convert it into a stable, humus-like material.

After composting, the next step is to crush and mix the compost with other organic materials such as bone meal, fish meal, and seaweed extract. This creates a homogeneous mixture that provides a balanced blend of nutrients to the plants.

The mixture is then granulated using an organic fertilizer granulator. The granulator compresses the mixture into small pellets or granules that are easy to handle and apply to the soil.

The granules are then dried using an organic fertilizer dryer, which removes any excess moisture and ensures that the granules are stable and long-lasting.

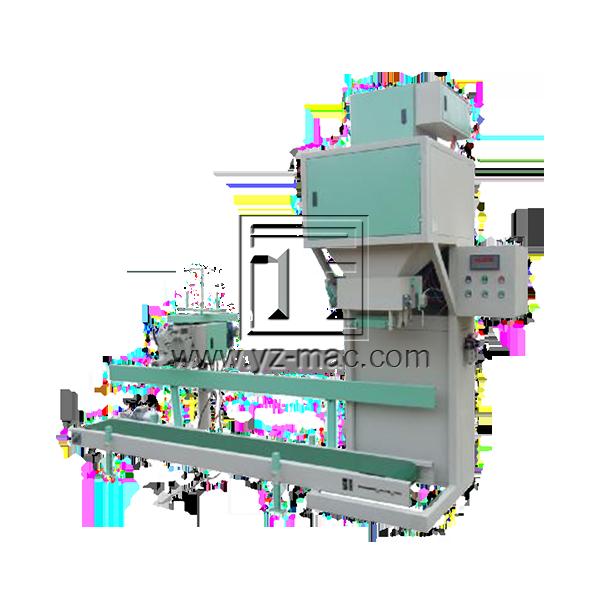

Finally, the dried granules are cooled and packaged for sale or storage. The packaging is usually done in bags or containers, and the granules are labeled with information about their nutrient content and recommended application rates.

Overall, the organic fertilizer production line is designed to produce high-quality fertilizers that are rich in essential nutrients and free from harmful chemicals. The process is environmentally friendly and helps to promote sustainable agriculture and food production.