Organic fertilizer production line

An organic fertilizer production line is a set of equipment and machinery used to produce organic fertilizers from organic materials such as animal manure, crop residues, and food waste. The production line usually consists of several stages, each with its own specific equipment and processes.

Here are the basic stages and equipment used in an organic fertilizer production line:

Pre-treatment stage: This stage involves collecting and pre-treating the raw materials, including shredding, crushing, and mixing. Equipment used in this stage include shredders, crushers, and mixers.

Fermentation stage: This stage involves the decomposition of the organic materials through a biological process called composting. Equipment used in this stage include compost turners, fermenters, and temperature control systems.

Drying stage: This stage involves drying the compost to reduce the moisture content to a suitable level for granulation. Equipment used in this stage include dryers and dehydrators.

Crushing and mixing stage: This stage involves crushing and mixing the dried compost with other additives to create a uniform mixture. Equipment used in this stage include crushers, mixers, and blenders.

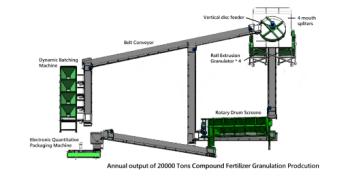

Granulation stage: This stage involves transforming the compost mixture into granules or pellets for easy application. Equipment used in this stage include granulators, pelletizers, and screening machines.

Packaging stage: This stage involves packaging the finished organic fertilizer into bags or other containers for storage and distribution. Equipment used in this stage include bagging machines and automatic weighing systems.

Overall, an organic fertilizer production line can be customized to suit the specific needs of the producer, including the capacity and type of organic materials used. A well-designed and efficient production line can help improve the quality and yield of organic fertilizers while reducing production costs.