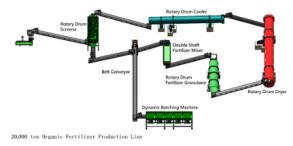

Organic fertilizer production equipment with an annual output of 20,000 tons

Organic fertilizer production equipment with an annual output of 20,000 tons typically consists of the following basic equipment:

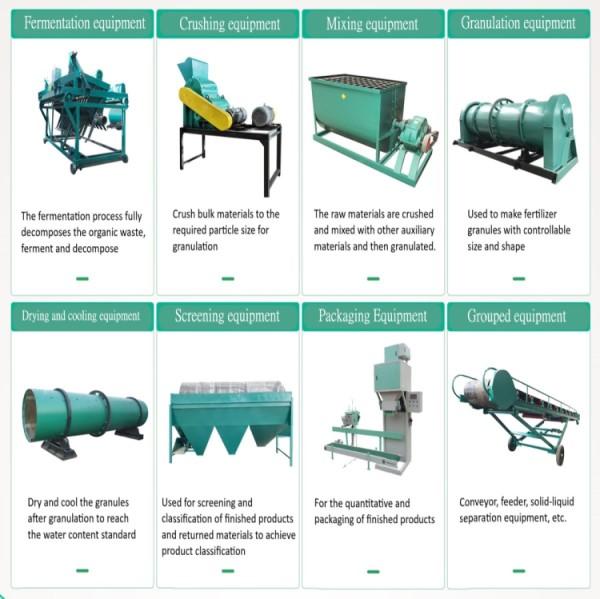

1.Composting Equipment: This equipment is used to ferment organic materials and convert them into high-quality organic fertilizers. Composting equipment can include a compost turner, a crushing machine, and a mixing machine.

2.Fermentation Equipment: This equipment is used to create optimal conditions for the microorganisms to break down the organic materials in the compost. Fermentation equipment can include a fermentation tank or a bio-reactor.

3.Drying Equipment: This equipment is used to dry the organic fertilizer to a moisture content suitable for storage and transportation. Drying equipment can include a rotary dryer or a belt dryer.

4.Cooling Equipment: This equipment is used to cool the dried organic fertilizer and make it ready for packaging. Cooling equipment can include a rotary cooler or a counterflow cooler.

5.Screening Equipment: This equipment is used to screen and grade the organic fertilizer according to particle size. Screening equipment can include a vibrating screen or a rotary screener.

6.Packaging Equipment: This equipment is used to pack the organic fertilizer into bags or other containers. Packaging equipment can include a bagging machine or a bulk packing machine.

Other Supporting Equipment: Depending on the specific production process, other supporting equipment may be required, such as conveyors, elevators, and dust collectors.

It is important to note that the specific equipment needed may vary depending on the type of organic fertilizer being produced, as well as the specific requirements of the production process. Additionally, automation and customization of the equipment may also impact the final list of required equipment.