Organic fertilizer production equipment

Organic fertilizer production equipment refers to the machines and tools used to manufacture organic fertilizers from organic materials such as animal manure, crop residues, and food waste.

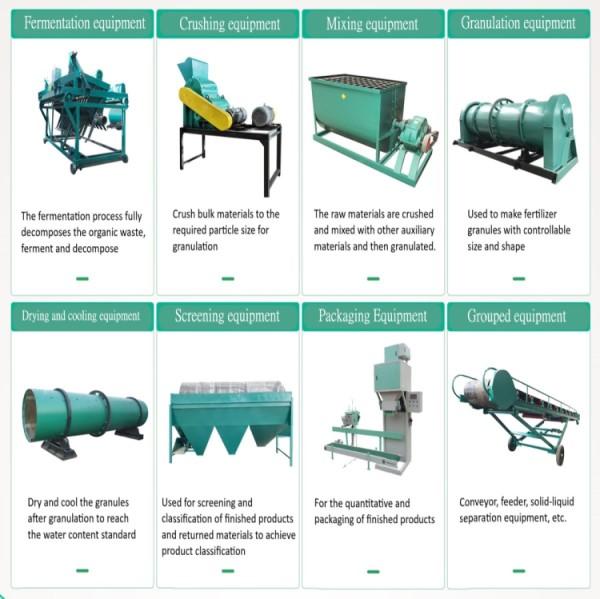

Some common types of organic fertilizer production equipment include:

Composting equipment: This includes compost turners, crushers, and mixers used to break down and mix organic materials to create a uniform compost mixture.

Drying equipment: This includes dryers and dehydrators used to remove excess moisture from the compost to make it suitable for storage and packaging.

Granulation equipment: This includes granulators and pelletizers used to transform the compost into granules or pellets for easier application.

Packaging equipment: This includes bagging machines and automatic weighing systems used to package the organic fertilizer into bags or other containers for distribution.

Storage equipment: This includes silos and other storage containers used to store the finished organic fertilizer until it is ready for use.

Crushing and mixing equipment: This includes crushers, mixers, and blenders used to break down and mix the raw materials needed to make organic fertilizers.

Screening equipment: This includes vibrating screens and sifters used to remove impurities from the finished organic fertilizer.

Overall, these equipment are essential for efficient and effective production of high-quality organic fertilizers.