Organic fertilizer production equipment

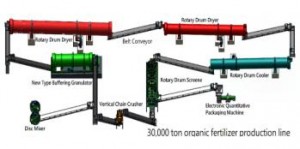

Organic fertilizer production equipment is specifically designed to process organic materials such as animal manure, crop residues, food waste, and other organic matter into high-quality organic fertilizers. The equipment typically includes several different machines that work together to convert the raw materials into finished organic fertilizers.

Some common types of organic fertilizer production equipment include:

1.Composting equipment: Used to turn organic waste materials into compost, which is a natural fertilizer. This includes compost turners, composting bins, and other equipment.

2.Fermentation equipment: Used to promote the decomposition of organic materials and produce high-quality organic fertilizers, including bio-reactors, vermicomposting systems, and aerobic fermentation machines.

3.Crushing and grinding equipment: Used to grind the raw materials into small particles, which helps speed up the composting or fermentation process.

4.Mixing and blending equipment: Used to combine different organic materials to create a homogeneous mixture, including mixers and blenders.

5.Granulating equipment: Used to convert the organic matter into granules or pellets for easier handling and application, including granulators and pelletizers.

6.Drying and cooling equipment: Used to reduce the moisture content of the organic fertilizers and prevent them from spoiling, including rotary dryers and coolers.

7.Screening and grading equipment: Used to remove any impurities or oversized particles from the organic fertilizer before packaging and distribution.

Organic fertilizer production equipment can be customized to suit different production capacities and requirements, depending on the specific needs of the user. The equipment is environmentally friendly and sustainable, helping to reduce the reliance on chemical fertilizers and improve soil health.