Organic Fertilizer Processing Machinery

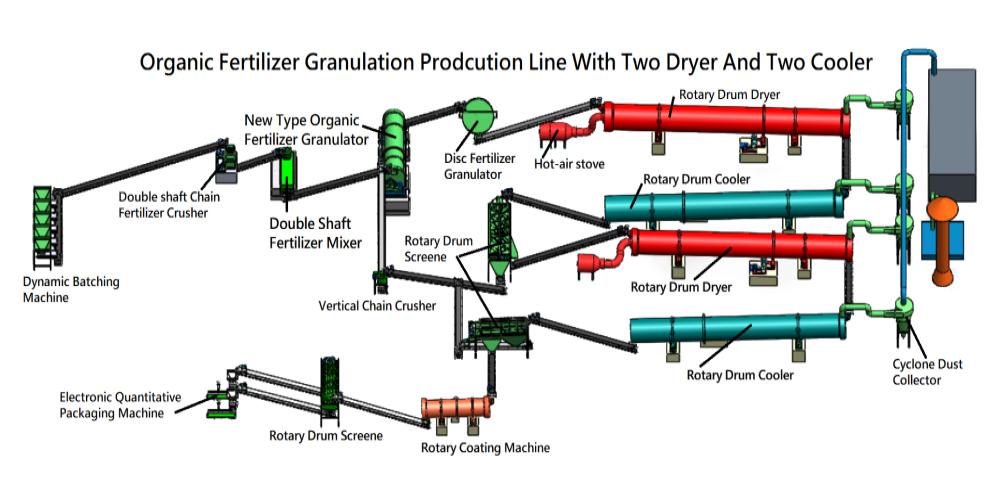

Organic fertilizer processing machinery refers to the equipment used in the production process of organic fertilizers. These machines are designed to convert organic waste materials into nutrient-rich fertilizers for plant growth. Organic fertilizer processing machinery includes several types of equipment such as:

1.Composting equipment: This equipment is used for the aerobic fermentation of organic materials such as animal manure, crop residues, and food waste.

2.Crushing and mixing equipment: These machines are used to crush and mix the fermented organic materials to form a homogenous mixture.

3.Granulating equipment: This equipment is used to granulate the mixed materials into round, uniform-sized granules.

4.Drying and cooling equipment: These machines are used to dry and cool the granules to ensure that they are suitable for storage and transport.

5.Screening and packing equipment: These machines are used to screen the final product and pack it into bags or containers for distribution.

Organic fertilizer processing machinery plays a critical role in the production of high-quality organic fertilizers that are essential for sustainable agriculture and healthy crop growth.