Organic Fertilizer Processing Line

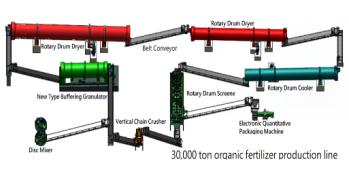

An organic fertilizer processing line typically consists of several steps and equipment, including:

1.Composting: The first step in organic fertilizer processing is composting. This is the process of decomposing organic materials such as food waste, manure, and plant residue into a nutrient-rich soil amendment.

2.Crushing and mixing: The next step is to crush and mix the compost with other organic materials such as bone meal, blood meal, and feather meal. This helps to create a balanced nutrient profile in the fertilizer.

3.Granulation: The mixed materials are then fed into a granulator, which turns them into small granules. This makes the fertilizer easier to handle and apply.

4.Drying: The granules are then dried to remove excess moisture and ensure that they are stable and will not spoil during storage.

5.Cooling: After drying, the granules are cooled to room temperature to prevent them from sticking together.

6.Screening: The cooled granules are then screened to remove any oversized or undersized particles and ensure that the fertilizer is of uniform size.

7.Packaging: The final step is to package the fertilizer in bags or other containers for distribution and sale.

Some of the equipment used in an organic fertilizer processing line includes compost turners, crushers, mixers, granulators, dryers, coolers, and screening machines. The specific equipment needed will depend on the scale of the operation and the desired output.