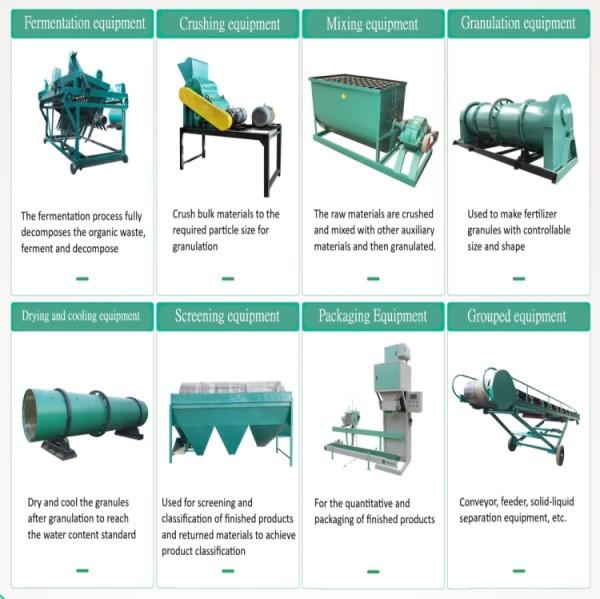

Organic fertilizer processing equipment

Organic fertilizer processing equipment includes various machines used in the production of organic fertilizers. Some of the common equipment used in organic fertilizer processing are:

Composting equipment: Composting is the first step in organic fertilizer production. The equipment used in this process includes compost turners, which are used to turn the organic materials to promote aerobic decomposition and accelerate the process.

Crushing and grinding equipment: Organic materials are often too large and bulky to be used directly in fertilizer production. Therefore, crushing and grinding equipment such as crushers, grinders, and shredders are used to break down the materials into smaller pieces.

Mixing and blending equipment: Once the organic materials are crushed or ground, they need to be mixed together in the right proportions to create a balanced organic fertilizer. This is where mixing and blending equipment such as mixers and blenders come into play.

Granulating equipment: Granulation is the process of forming the organic fertilizer into pellets or granules. The equipment used in this process includes granulators, pelletizers, and briquetting machines.

Drying equipment: After granulation, the organic fertilizer needs to be dried to remove excess moisture and prevent the growth of microorganisms. The equipment used in this process includes dryers, dehydrators, and rotary drum dryers.

Cooling equipment: The organic fertilizer needs to be cooled down after drying to prevent overheating and spoilage. The equipment used in this process includes coolers and rotary drum coolers.

Screening and grading equipment: The final step in organic fertilizer production is screening and grading to remove any impurities and ensure the final product meets the desired quality standards. The equipment used in this process includes screens, sifters, and classifiers.