Organic Fertilizer Processing Equipment

Organic fertilizer processing equipment refers to the machinery and equipment used in the production of organic fertilizer from organic materials. Here are some common types of organic fertilizer processing equipment:

1.Composting equipment: This includes machines used for the decomposition and stabilization of organic materials, such as compost turners, in-vessel composting systems, windrow composting systems, aerated static pile systems, and biodigesters.

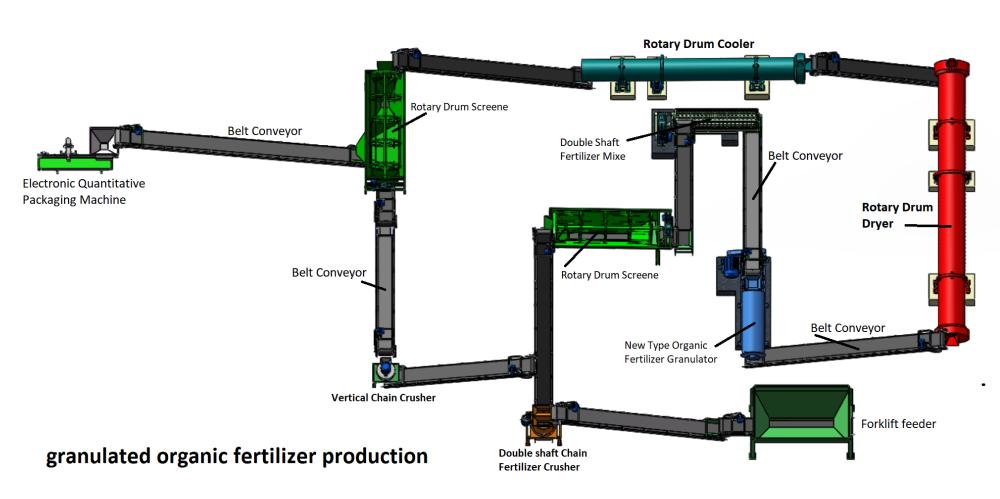

2.Crushing and grinding equipment: This includes machines used to break down large organic materials into smaller pieces, such as crushers, grinders, and shredders.

3.Mixing and blending equipment: This includes machines used to blend organic materials together in the right proportions, such as mixing machines, ribbon blenders, and screw mixers.

4.Granulation equipment: This includes machines used to transform the blended organic materials into granules or pellets, such as granulators, pelletizers, and extruders.

5.Drying and cooling equipment: This includes machines used to remove excess moisture from the granules or pellets, such as rotary dryers, fluidized bed dryers, and counter-flow coolers.

6.Screening and grading equipment: This includes machines used to separate the granules or pellets into different sizes, such as rotary screeners, vibratory screeners, and air classifiers.

7.Packing and bagging equipment: This includes machines used to package the final product into bags or other containers, such as bagging machines, weighing and filling machines, and sealing machines.

8.Fermentation equipment: This includes machines used to ferment the organic materials, such as aerobic fermenters, anaerobic digesters, and vermicomposting systems.

The specific organic fertilizer processing equipment needed will depend on the scale and type of organic fertilizer production being undertaken, as well as the available resources and budget. It is important to choose equipment that is appropriate for the type and quantity of organic materials being processed, as well as the desired quality of the final fertilizer.