Organic fertilizer pellet making machine

An organic fertilizer pellet making machine is a specialized equipment designed to convert organic waste materials into compact and nutrient-rich pellets. This machine offers an efficient and eco-friendly solution for recycling organic waste and producing high-quality organic fertilizer.

Benefits of an Organic Fertilizer Pellet Making Machine:

Waste Recycling: The organic fertilizer pellet making machine enables the conversion of organic waste materials, such as agricultural residues, food waste, animal manure, and green waste, into valuable fertilizer pellets. This process reduces waste disposal and contributes to a circular economy by recycling organic materials.

Nutrient-Rich Pellets: Organic fertilizer pellets produced by the pellet making machine are rich in essential nutrients, including nitrogen, phosphorus, and potassium, as well as micronutrients and organic matter. These pellets provide a balanced nutrient profile for plants, promoting healthy growth and improved soil fertility.

Controlled Release of Nutrients: Organic fertilizer pellets are designed to release nutrients slowly and steadily, providing a consistent and long-lasting supply of nutrients to plants. This controlled-release feature minimizes nutrient leaching and helps prevent nutrient imbalances in the soil, resulting in optimal plant uptake and reduced environmental impact.

Easy Application: Organic fertilizer pellets are convenient to handle, transport, and apply. Their uniform size and shape allow for precise and even distribution, ensuring efficient nutrient delivery to plants. The pellets can be applied through various methods, including broadcasting, side dressing, and incorporation into potting mixes.

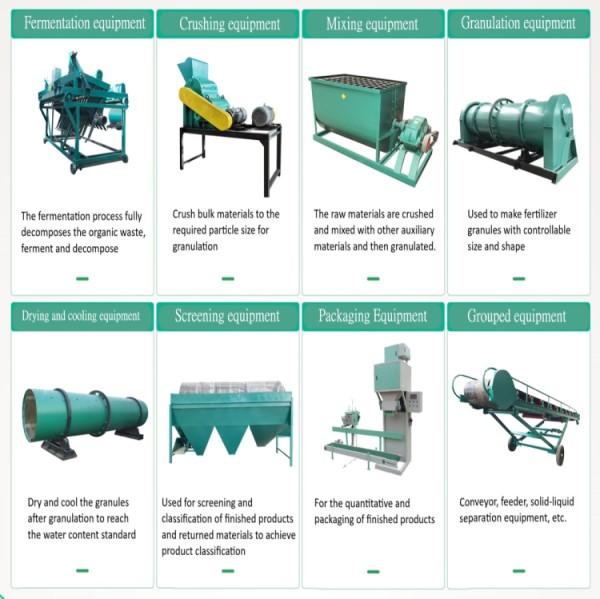

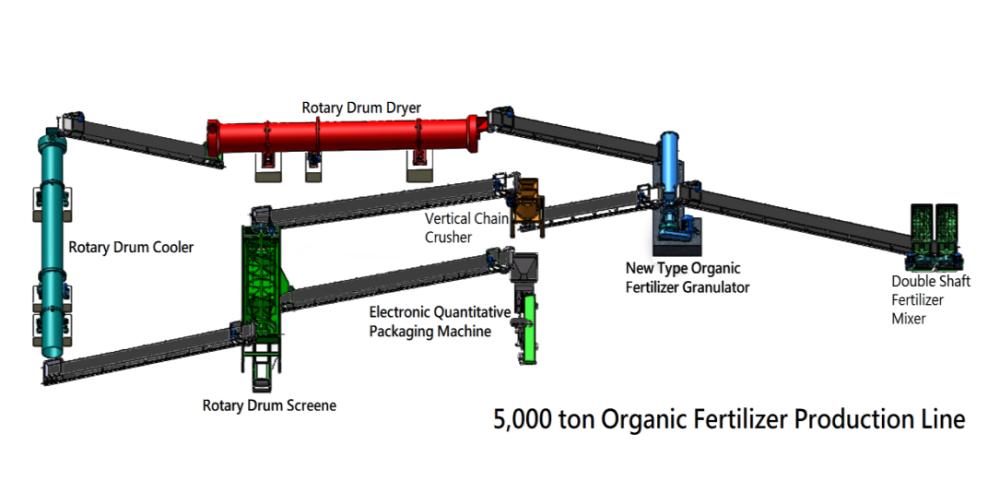

Pelletizing Process:

The organic fertilizer pellet making machine utilizes a pelletizing process to transform organic waste into pellets. The process typically involves the following steps:

Raw Material Preparation: Organic waste materials are collected and prepared for pelletization. This may involve shredding or grinding the materials to achieve a consistent particle size suitable for the pelletizing machine.

Mixing and Conditioning: The prepared organic waste materials are mixed with additional components, such as mineral additives or microbial inoculants, to enhance the nutrient content and microbial activity in the final pellets. The mixture is conditioned to achieve the desired moisture level for pellet formation.

Pellet Formation: The conditioned material is fed into the pellet making machine, where it undergoes compression and extrusion processes. The machine applies pressure and heat to the material, forming it into cylindrical or spherical pellets of uniform size.

Cooling and Drying: The freshly formed pellets are cooled to stabilize their structure and remove excess moisture. The pellets are then dried to the desired moisture content, ensuring storage stability and preventing microbial growth.

Applications of Organic Fertilizer Pellets:

Agriculture and Crop Production: Organic fertilizer pellets are widely used in agriculture for improving soil fertility and enhancing crop yields. The slow-release nature of the pellets ensures a consistent supply of nutrients to plants, promoting healthy growth, improved nutrient uptake, and higher crop quality.

Horticulture and Gardening: Organic fertilizer pellets are essential in horticulture and gardening applications. They provide a sustainable and organic alternative to synthetic fertilizers, enriching the soil with nutrients and organic matter. The pellets support the growth of flowers, vegetables, fruits, and ornamental plants, contributing to vibrant and healthy gardens.

Landscaping and Turf Management: Organic fertilizer pellets are used in landscaping and turf management to promote the health and vigor of lawns, sports fields, and golf courses. The slow-release nutrients in the pellets ensure long-lasting nourishment for the grass, enhancing its resilience, color, and overall appearance.

Organic Farming: Organic fertilizer pellets are a key component of organic farming practices. They help maintain soil health, improve soil structure, and support the growth of organic crops without the use of synthetic chemicals. The pellets contribute to sustainable agriculture by enriching the soil with organic matter and nutrients.

An organic fertilizer pellet making machine offers a sustainable solution for converting organic waste into nutrient-rich pellets. These pellets provide a balanced nutrient profile and ensure the controlled release of nutrients, promoting healthy plant growth and improving soil fertility. The pelletizing process transforms organic waste into a valuable resource, reducing waste disposal and supporting a circular economy.