Organic Fertilizer Making Machine

Organic fertilizer making machines are specialized equipment designed for the production of organic fertilizers. They are used in the manufacturing process of organic fertilizers from raw materials such as animal manure, agricultural waste, food waste, and other organic materials. The machines are designed to handle different stages of the fertilizer production process, including composting, grinding, mixing, granulating, drying, and packaging.

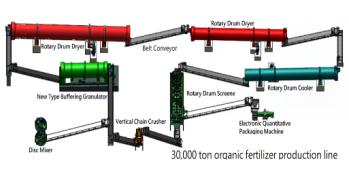

Some common types of organic fertilizer making machines include:

1.Compost turner: This machine is used for mixing and turning organic materials during the composting process, which accelerates decomposition and produces high-quality organic fertilizer.

2.Crusher: This machine is used for crushing and grinding raw materials such as agricultural waste, animal manure, and food waste into small particles, making it easier for further processing.

3.Mixer: This machine is used for blending different materials and creating a uniform mixture of raw materials for use in the granulation process.

4.Granulator: This machine is used for converting the mixture of raw materials into small particles or granules.

5.Dryer: This machine is used for drying the organic fertilizer granules to reduce moisture content and increase shelf life.

6.Cooler: This machine is used to cool the organic fertilizer granules after drying, which helps prevent clumping and improves product quality.

7.Packaging machine: This machine is used for packing the finished organic fertilizer into bags for storage and transportation.

These machines can be used individually or in combination to form a complete organic fertilizer production line.