Organic fertilizer granule making machine

An organic fertilizer granule making machine is a specialized equipment designed to convert organic materials into uniform granules for efficient and convenient application. This machine plays a crucial role in the organic fertilizer production process by transforming raw organic materials into granules that are easier to handle, store, and distribute.

Benefits of an Organic Fertilizer Granule Making Machine:

Enhanced Nutrient Availability: The granulation process breaks down organic materials into smaller particles, increasing the surface area available for microbial activity. This promotes the decomposition of organic matter, releasing essential nutrients in a more accessible form for plant uptake. Granules provide a controlled release of nutrients, ensuring a steady supply to plants over an extended period.

Improved Handling and Application: Organic fertilizer granules are easier to handle and apply compared to raw organic materials. The uniform size and shape of the granules allow for consistent spreading, reducing the risk of over- or under-fertilization. The granules can be conveniently applied by hand, with spreaders, or incorporated into soil using seeding equipment.

Reduced Nutrient Loss and Environmental Impact: Organic fertilizer granules have a lower risk of nutrient loss through leaching or volatilization compared to unprocessed organic materials. The granules release nutrients gradually, reducing the likelihood of nutrient runoff and minimizing their environmental impact. This ensures efficient nutrient utilization and supports sustainable agricultural practices.

Working Principle of an Organic Fertilizer Granule Making Machine:

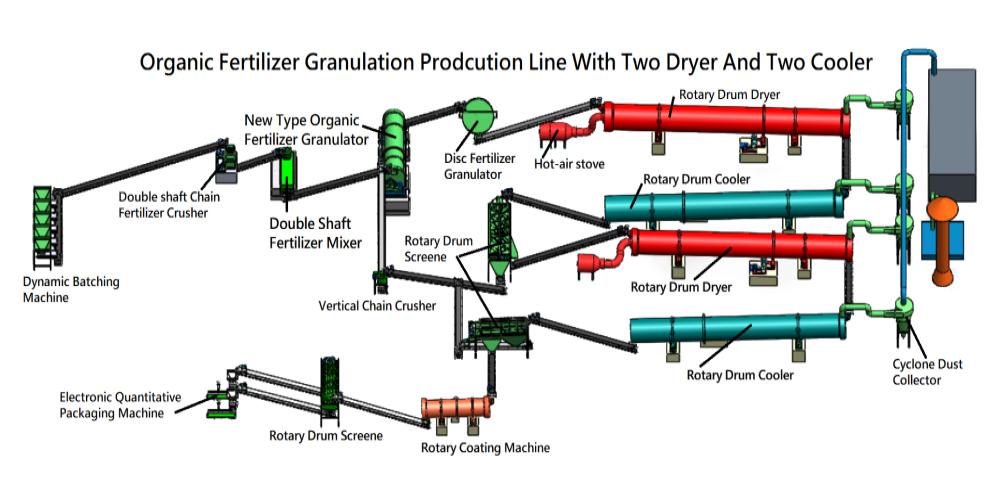

Organic fertilizer granule making machines typically utilize a process known as wet granulation. The machine combines the organic materials with a binding agent, such as water or a natural adhesive, to form a paste-like mixture. The mixture is then forced through a specially designed die or plate with small holes. As the material passes through the holes, it is cut into granules of uniform size. The granules are then dried and cooled to obtain the final organic fertilizer product.

Applications of Organic Fertilizer Granules:

Agriculture and Crop Production: Organic fertilizer granules provide essential nutrients to crops, improving soil fertility and promoting healthy plant growth. They can be applied during sowing or planting, topdressed onto the soil surface, or incorporated into the soil prior to cultivation. The controlled release of nutrients from the granules ensures optimal nutrient availability throughout the crop’s growth cycle.

Horticulture and Gardening: Organic fertilizer granules are widely used in horticultural practices, including greenhouse cultivation, flower beds, and home gardens. The granules support the growth of ornamental plants, vegetables, herbs, and fruit trees, providing a balanced supply of nutrients for healthy plant development and abundant yields.

Organic Farming: Organic farmers rely on organic fertilizer granules to meet the nutrient requirements of their crops while adhering to organic farming principles. The granules offer a sustainable and environmentally friendly alternative to synthetic fertilizers, enriching the soil with organic matter and promoting long-term soil health.

Soil Improvement and Restoration: Organic fertilizer granules can be used for soil improvement and land restoration projects. They help rejuvenate degraded soils, remediate contaminated lands, and enhance soil fertility in areas affected by erosion or nutrient depletion. The slow-release nature of the granules provides a gradual and sustained nutrient supply for soil rehabilitation.

An organic fertilizer granule making machine is a valuable tool in the production of high-quality organic fertilizer. By converting raw organic materials into uniform granules, this machine enhances nutrient availability, improves handling and application convenience, and reduces nutrient loss and environmental impact. Organic fertilizer granules find applications in agriculture, horticulture, organic farming, and soil improvement projects. Their controlled release of nutrients ensures optimal plant growth, sustainable nutrient management, and the promotion of healthy and productive ecosystems.

.jpg)