Organic fertilizer granule machine

An organic fertilizer granule machine is a specialized equipment designed to transform organic materials into granules or pellets for efficient and convenient application. This machine plays a crucial role in the organic fertilizer production process by converting raw materials into uniform granules that are easier to handle, store, and distribute.

Benefits of an Organic Fertilizer Granule Machine:

Enhanced Nutrient Release: Organic fertilizer granules provide a controlled release of nutrients to plants over an extended period. The granules break down gradually, releasing nutrients in a consistent and targeted manner, ensuring optimal nutrient availability for plant growth and minimizing nutrient loss through leaching or volatilization.

Improved Fertilizer Efficiency: The granulation process improves the efficiency of organic fertilizers by reducing nutrient loss and increasing nutrient uptake by plants. Granules help prevent nutrient runoff during rainfall or irrigation, minimizing environmental impact and maximizing the utilization of applied nutrients.

Ease of Application: Organic fertilizer granules are uniform in size and shape, making them easier to handle, spread, and incorporate into the soil. The granules provide better coverage and distribution, ensuring a more even application and reducing the risk of nutrient imbalance in the soil.

Long Shelf Life: Granulated organic fertilizers have a longer shelf life compared to raw organic materials. The granules are less susceptible to moisture absorption, caking, or nutrient degradation, ensuring the quality and effectiveness of the fertilizer product over an extended period.

Working Principle of an Organic Fertilizer Granule Machine:

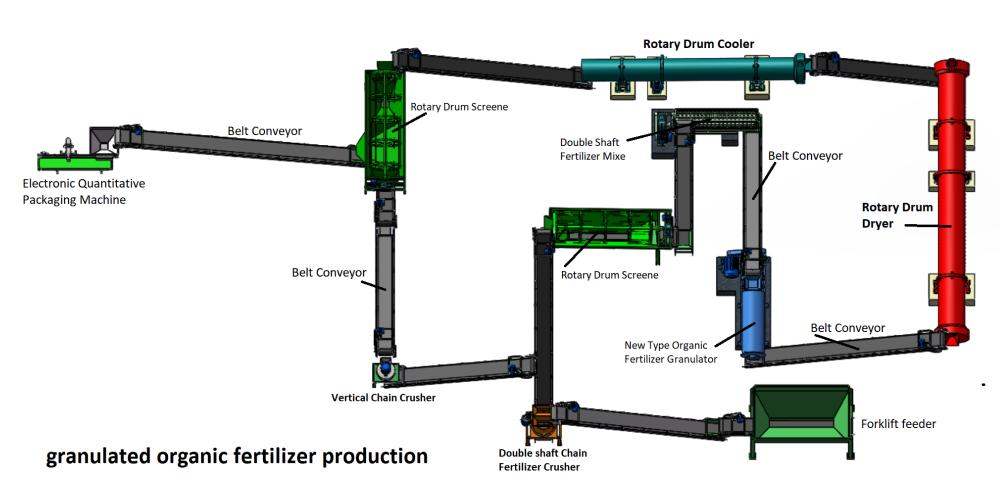

An organic fertilizer granule machine utilizes a combination of mechanical force and chemical binding agents to transform organic materials into granules. The machine typically consists of a granulation chamber or drum, where the raw materials are mixed, moistened, and agglomerated. As the drum rotates, the materials adhere together, forming granules of uniform size. Depending on the specific machine design, the granules may undergo drying and cooling processes to further enhance their stability and quality.

Applications of Organic Fertilizer Granule Machines:

Agriculture and Crop Production: Organic fertilizer granule machines are widely used in agriculture and crop production. The granules provide a convenient and efficient way to supply essential nutrients to plants, improving soil fertility, promoting healthy growth, and increasing crop yields. The controlled-release nature of the granules ensures long-term nutrient availability and reduces the frequency of fertilizer application.

Gardening and Horticulture: Organic fertilizer granules are highly beneficial in gardening and horticulture applications. The granules offer a convenient means of enriching garden soils, container plants, and ornamental gardens with organic nutrients. The uniform size and shape of the granules allow for easier blending, application, and precise nutrient delivery.

Organic Farming: Organic farmers utilize organic fertilizer granules to meet the nutritional requirements of their crops while adhering to organic farming principles. The granules provide a sustainable and environmentally friendly approach to soil fertility management, reducing reliance on synthetic fertilizers and minimizing the risk of environmental pollution.

Soil Remediation and Land Restoration: Organic fertilizer granules play a role in soil remediation and land restoration projects. They help improve soil structure, enhance microbial activity, and promote the recovery of degraded or contaminated soils. The controlled-release properties of the granules ensure gradual nutrient release, supporting the establishment of vegetation and the rehabilitation of damaged land areas.

An organic fertilizer granule machine is a valuable tool for enhancing fertilizer efficiency, nutrient availability, and soil health. The controlled-release nature of organic fertilizer granules provides consistent and targeted nutrient delivery to plants, reducing nutrient loss and improving fertilizer utilization. Whether in agriculture, gardening, organic farming, or land restoration projects, organic fertilizer granules offer convenience, efficiency, and environmental sustainability.