Organic fertilizer granulator

An organic fertilizer granulator is a machine used to convert organic materials such as animal manure, plant residues, and food waste into granular fertilizers. Granulation is a process that involves agglomerating small particles into larger particles, making them easier to handle, transport, and apply to crops.

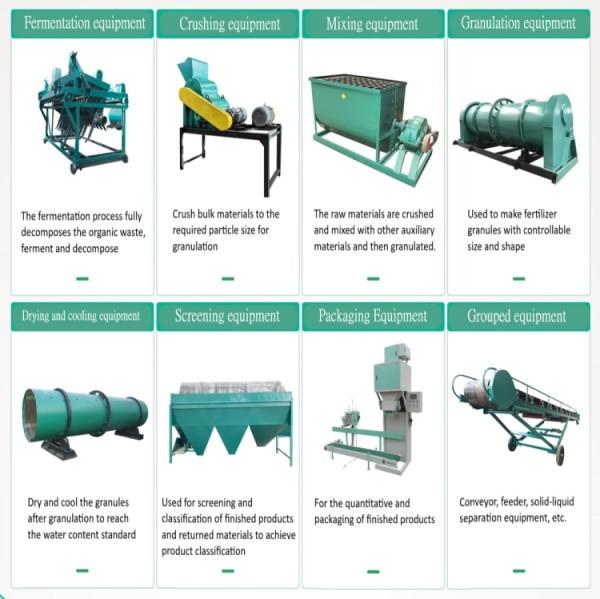

Organic fertilizer granulators come in different types, including rotary drum granulators, disc granulators, and flat die granulators. They use different mechanisms to create granules, but the general process involves the following steps:

1.Preparation of raw materials: The organic materials are first dried and ground into small particles.

2.Mixing: The ground materials are then mixed with other additives such as lime, microbial inoculants, and binders to promote granulation.

3.Granulation: The mixed materials are fed into the granulator machine, where they are agglomerated into granules by a rolling, compressing, or rotating action.

4.Drying and cooling: The newly formed granules are then dried and cooled to remove excess moisture and prevent caking.

5.Screening and packaging: The final step involves screening the granules to remove any oversized or undersized particles and packaging them for distribution.

Organic fertilizer granulation offers several benefits over other forms of organic fertilizers. The granules are easy to handle, store, and transport, making them more convenient for farmers to use. Granulated fertilizers also provide a slow-release of nutrients to crops, ensuring sustained growth and productivity. Additionally, organic fertilizer granules are less prone to leaching, reducing the risk of groundwater contamination.