Organic fertilizer granulation machine

An organic fertilizer granulation machine is a specialized equipment designed to convert organic materials into uniform granules, making them easier to handle, store, and apply. This process, known as granulation, improves the nutrient content, reduces moisture content, and enhances the overall quality of organic fertilizers.

Benefits of an Organic Fertilizer Granulation Machine:

Improved Nutrient Efficiency: Granulation increases the nutrient availability and absorption rate of organic fertilizers. By converting organic materials into granules, the surface area of the fertilizer is reduced, preventing nutrient loss through leaching or volatilization. This ensures that a higher percentage of nutrients are efficiently utilized by plants, leading to improved crop productivity.

Controlled Release of Nutrients: Organic fertilizer granules are designed to release nutrients gradually, providing a sustained supply over an extended period. This controlled release mechanism reduces the risk of nutrient imbalances, prevents nutrient wastage, and minimizes environmental impacts. It promotes balanced plant growth and reduces the need for frequent fertilizer applications.

Ease of Handling and Application: Granulated organic fertilizers are uniform in size and shape, making them easier to handle, transport, and apply. The granules flow smoothly through fertilizer spreaders, ensuring even distribution across the field. This enhances application efficiency, reduces labor requirements, and improves overall fertilizer management.

Reduced Moisture Content: The granulation process removes excess moisture from organic materials, resulting in granules with reduced moisture content. This enhances the stability and shelf life of the organic fertilizer, preventing caking or clumping during storage. It also reduces the risk of microbial activity and nutrient loss due to moisture-related processes.

Working Principle of an Organic Fertilizer Granulation Machine:

Organic fertilizer granulation machines employ various techniques to convert organic materials into granules. The most commonly used methods include:

Disc Granulation: This method involves rotating a disc or pan to agglomerate the organic materials into granules. The addition of binders or additives may be used to enhance the granulation process.

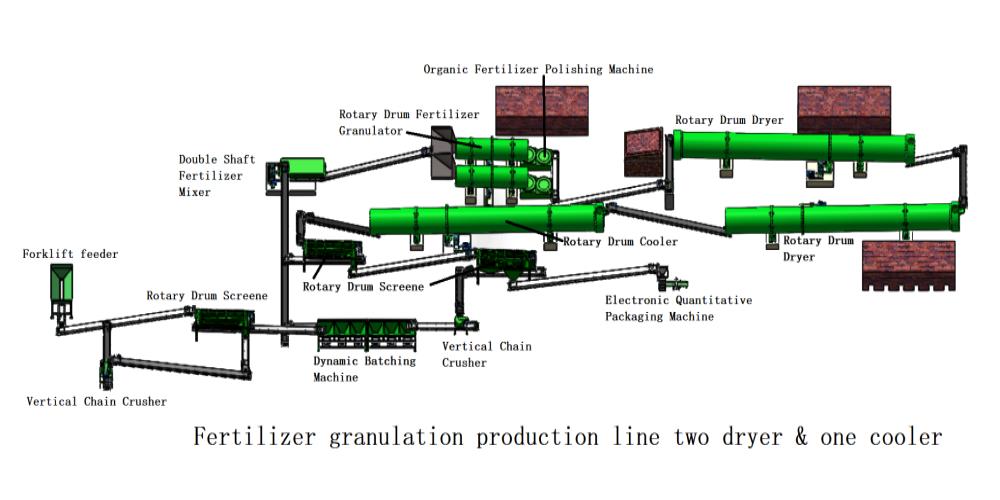

Rotary Drum Granulation: In this method, a rotary drum is used to agitate and roll the organic materials, gradually forming granules. The addition of a liquid binder or spray system aids in the granulation process.

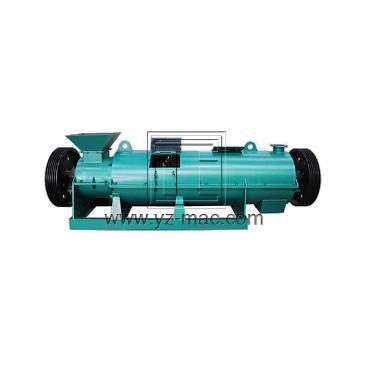

Extrusion Granulation: This method utilizes an extruder to force the organic materials through a die, forming cylindrical or spherical granules. The extrusion process applies pressure and heat to facilitate granule formation.

Applications of Organic Fertilizer Granulation Machines:

Agricultural Crop Production: Organic fertilizer granulation machines play a vital role in sustainable agriculture by providing an efficient means of nutrient supply to crops. Granulated organic fertilizers can be applied directly to the soil or incorporated into the planting hole during seeding or transplanting. They promote soil health, improve nutrient availability, and enhance crop productivity.

Horticulture and Greenhouse Cultivation: Granulated organic fertilizers are widely used in horticulture, greenhouse cultivation, and nurseries. They provide controlled-release nutrients for potted plants, container gardens, and ornamental crops. Granules can be easily incorporated into growing media or applied as a topdressing for continuous nutrient supply.

Organic Farming Practices: Organic fertilizer granulation machines are essential tools in organic farming systems. They allow organic farmers to efficiently convert organic waste materials, crop residues, and animal manures into high-quality granulated fertilizers. This promotes the use of organic inputs, minimizes reliance on synthetic fertilizers, and supports sustainable farming practices.

Soil Rehabilitation and Land Restoration: Organic fertilizer granulation machines are employed in soil rehabilitation and land restoration projects. Granulated organic fertilizers are applied to degraded soils, mining sites, or land undergoing reclamation. They improve soil fertility, enhance nutrient levels, and promote vegetation establishment, aiding in the restoration of land ecosystems.

An organic fertilizer granulation machine is a valuable tool for improving nutrient efficiency, promoting sustainable agriculture, and enhancing soil health. The benefits of using a granulation machine include improved nutrient availability, controlled release of nutrients, ease of handling and application, and reduced moisture content.