Organic fertilizer fermentation equipment

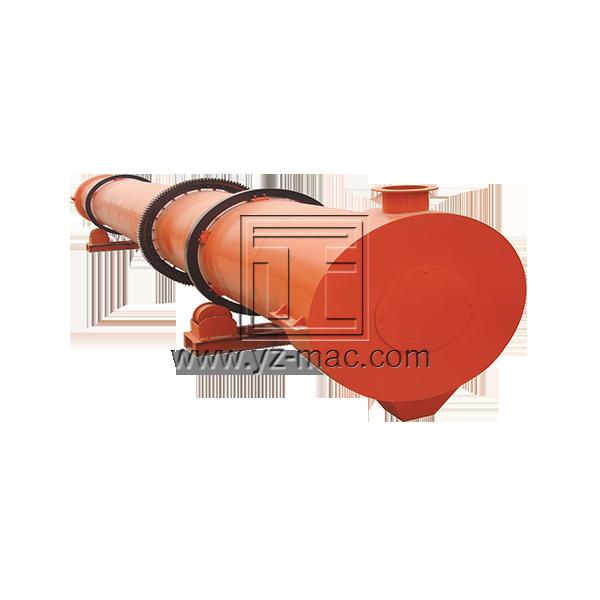

Organic fertilizer fermentation equipment is used to ferment and decompose organic materials such as animal manure, crop straw, and food waste into high-quality organic fertilizer. The main purpose of the equipment is to create a suitable environment for microbial activity, which breaks down the organic matter and converts it into useful nutrients for plants.

Organic fertilizer fermentation equipment typically includes a fermentation tank, mixing equipment, temperature and moisture control systems, and a compost turning machine. The fermentation tank is where the organic materials are placed and allowed to decompose, with the mixing equipment ensuring that the materials are evenly distributed and oxygen is supplied to the microorganisms. The temperature and moisture control systems ensure that the environment within the tank is optimal for microbial activity, with the compost turning machine used to aerate the materials and speed up the decomposition process.

Overall, organic fertilizer fermentation equipment plays a crucial role in the production of high-quality organic fertilizer, providing an efficient and environmentally friendly solution for recycling organic waste materials.