Organic fertilizer equipment

The choice of raw materials for organic fertilizer and bio-organic fertilizer can be various livestock manure and organic waste. The basic production formula varies with different types and raw materials; the basic raw materials are: chicken manure, duck manure, goose manure, pig manure , Cattle and sheep dung, crop straw, sugar industry filter mud, bagasse, sugar beet residue, distiller's grains, medicine residue, furfural residue, fungus residue, bean cake, cotton seed cake, rapeseed cake, grass charcoal, etc.

The fermentation of bio-organic raw materials plays a very important role in the entire organic fertilizer production process. Sufficient fermentation is the basis for the production of high-quality organic fertilizer. The pile turning machine realizes thorough fermentation and composting, and can realize high pile turning and fermentation, which improves the speed of aerobic fermentation. The fermentation process fully decomposes the organic waste and decomposes.

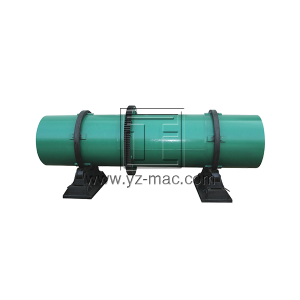

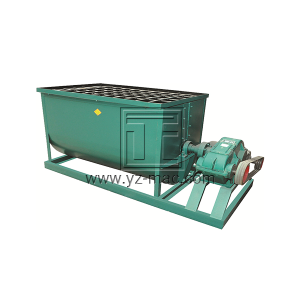

The general production process of organic fertilizer includes fermentation, mixing, crushing, granulation, drying, cooling, fertilizer screening, packaging, etc.

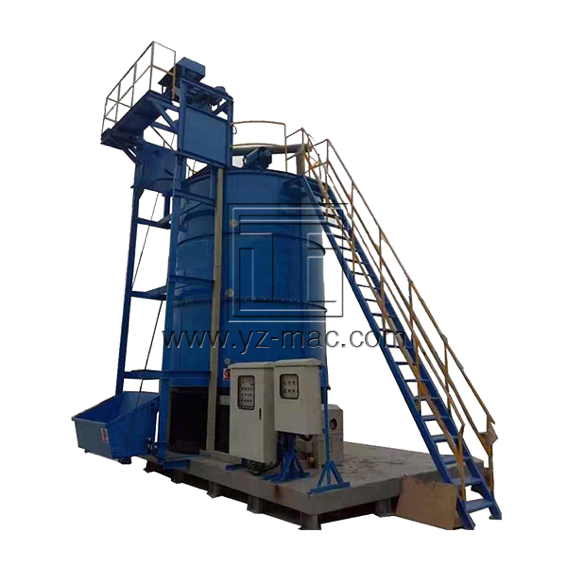

The organic fertilizer fermentation tank is mainly an integrated sludge treatment equipment for high-temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, biological decomposition, and resource utilization.

● Vertical design taking a small occupy space

● Close or sealing fermentation, no odor in the air

● l Wide application to city/life/food/garden/sewage waste treatment

● Electric heating to transfer oil with cotton thermal insulation

● Inner can be stainless steel plate with thickness 4-8mm

● With insulating layer jacket to improve the composting temperature

● With power cabinet to control the temperature automatically

● Easy use and maintain and can reach self-cleaning

● Paddle mixing shaft can reach complete and full mixing and blending materials