Organic fertilizer equipment

Organic fertilizer is a kind of green environmental protection, pollution-free, stable organic chemical properties, rich in nutrients, and harmless to the soil environment. It is favored by more and more farmers and consumers. The key to the production of organic fertilizer is organic fertilizer equipment , Let’s take a look at the main types and characteristics of organic fertilizer equipment.

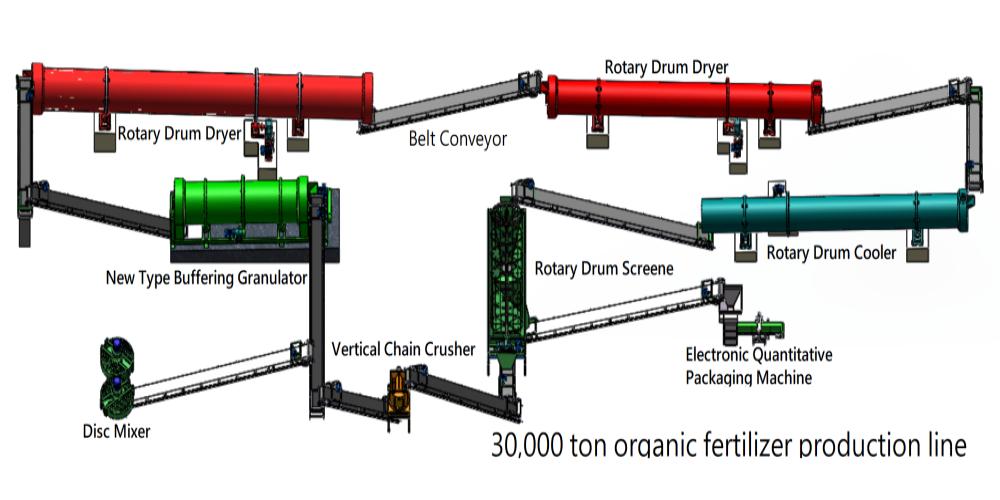

Compost turner: The compost turner is an indispensable equipment in the process of organic fertilizer production. It is mainly used for turning and mixing organic raw materials to accelerate the fermentation speed of compost. The compost turning machine is characterized by simple operation and high production efficiency, which can effectively turn organic raw materials and improve their fermentation efficiency. It is an indispensable link in the production process of organic fertilizers. Mixer: The mixer is mainly used in the production process of organic fertilizer to mix and stir the fermented organic raw materials and additives, so as to better deploy the nutrients of the organic fertilizer and improve the quality of the organic fertilizer. The characteristic of the mixer is that it can quickly and evenly mix organic raw materials, improve the quality of organic fertilizer, and is easy to operate, which can improve production efficiency.

Pulverizers: Pulverizers are mainly used for the grinding and crushing of organic raw materials, making it easier for mixing, composting and granulation of finished products. The characteristic of the pulverizer is that it can pulverize a variety of raw materials, is easy to operate, and can improve production efficiency.

Granulator: The granulator is mainly used in the molding process of organic fertilizer to process the prepared organic raw materials into granular products. The granulator is characterized by stable finished product quality, simple operation and high production efficiency.

Dryer: The dryer is mainly used for drying finished organic fertilizers to remove moisture and improve the shelf life of organic fertilizers. “