Organic fertilizer crushing equipment

Send email to us

Previous:

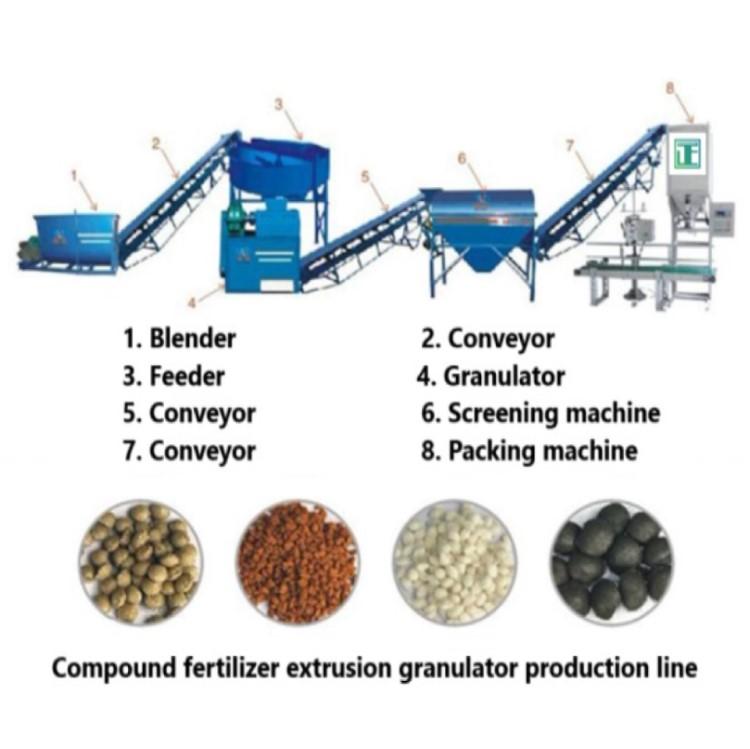

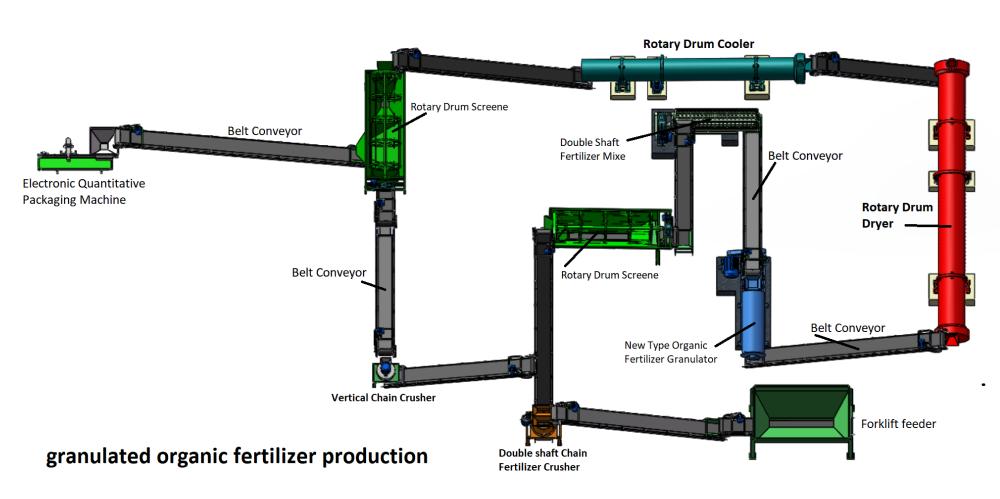

Organic fertilizer granulation equipment

Next:

Organic fertilizer mixing equipment

Organic fertilizer crushing equipment is used to crush the fermented organic materials into fine particles. This equipment can crush the materials such as straw, soybean meal, cottonseed meal, rapeseed meal, and other organic materials to make them more suitable for granulation. There are different types of organic fertilizer crushing equipment available, including chain crusher, hammer crusher, and cage crusher. These machines can effectively break down the organic materials into small pieces, making them easier to handle during the granulation process.

Write your message here and send it to us