Organic fertilizer continuous drying equipment

Organic fertilizer continuous drying equipment is a type of drying equipment that is designed to dry organic fertilizer continuously. This equipment is often used in large-scale organic fertilizer production plants, where large quantities of organic materials need to be dried to remove excess moisture before further processing.

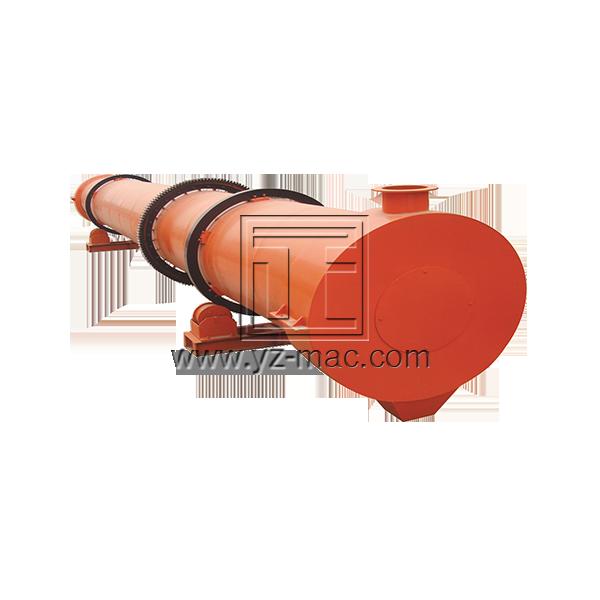

There are several types of organic fertilizer continuous drying equipment available, including rotary drum dryers, flash dryers, and fluidized bed dryers. Rotary drum dryers are the most commonly used type of continuous dryer for organic fertilizer production. They consist of a rotating drum that is heated by a hot gas stream, which dries the organic material as it is tumbled inside the drum.

Flash dryers are another type of continuous dryer that is commonly used for organic fertilizer production. They work by rapidly heating and drying the organic material in a short amount of time, usually less than a second. This is achieved by injecting hot gas into a chamber that contains the organic material, causing it to evaporate the moisture and leave behind a dry product.

Fluidized bed dryers are also used for drying organic fertilizer on a continuous basis. They work by suspending the organic material in a stream of hot gas, which dries the material as it flows through the dryer. The fluidized bed dryer is often used for heat-sensitive materials, as it provides gentle drying without damaging the material.

Overall, organic fertilizer continuous drying equipment plays an important role in the production of high-quality organic fertilizers by removing excess moisture from the organic material, improving its shelf life, and making it easier to handle and transport.