Organic fertilizer coating equipment

Organic fertilizer coating equipment is used to add a protective or functional layer on the surface of organic fertilizer pellets. The coating can help to prevent moisture absorption and caking, reduce dust generation during transportation, and control nutrient release.

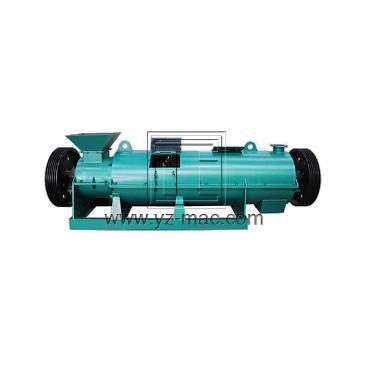

The equipment typically includes a coating machine, a spraying system, and a heating and cooling system. The coating machine has a rotating drum or disc that can evenly coat the fertilizer pellets with the desired material. The spraying system delivers the coating material onto the pellets in the machine, and the heating and cooling system controls the temperature of the pellets during the coating process.

The coating materials used for organic fertilizer can vary depending on the specific needs of the crop and soil. Common materials include clay, humic acid, sulfur, and biochar. The coating process can be adjusted to achieve different coating thicknesses and compositions.