Organic compost machine

An organic compost machine is a revolutionary solution that transforms organic waste materials into nutrient-rich compost, contributing to sustainable waste management and soil enrichment. With its innovative technology, this machine efficiently converts various organic waste materials into valuable compost, reducing landfill waste and promoting environmental conservation.

Benefits of an Organic Compost Machine:

Waste Reduction: An organic compost machine plays a vital role in waste reduction by processing organic waste materials. It diverts food waste, yard trimmings, agricultural residues, and other organic materials from landfills, minimizing the environmental impact and reducing greenhouse gas emissions associated with waste decomposition.

Nutrient Recycling: The organic compost machine breaks down organic waste into compost, a nutrient-rich soil amendment. By recycling nutrients from organic waste, the machine facilitates the creation of a valuable resource that can be reintroduced into the soil, replenishing essential nutrients and promoting plant growth.

Soil Improvement: The compost produced by an organic compost machine enhances soil fertility, structure, and water-holding capacity. It enriches the soil with organic matter, improving nutrient availability and soil biodiversity. Additionally, compost improves soil structure, allowing for better water infiltration and retention, reducing erosion, and promoting sustainable land management practices.

Cost Savings: By utilizing an organic compost machine, businesses and individuals can reduce waste disposal costs. Instead of paying for waste removal or purchasing commercial fertilizers, they can transform their organic waste into compost, an economical and sustainable soil amendment.

Working Principle of an Organic Compost Machine:

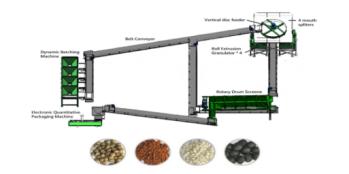

An organic compost machine employs a combination of mechanical, biological, and temperature control processes to accelerate composting. The machine creates an ideal environment for microorganisms to break down organic waste. It regulates temperature, moisture, and aeration levels to facilitate microbial activity and optimize decomposition. Some machines use automatic turning or mixing mechanisms to ensure even distribution of organic waste and enhance composting efficiency.

Applications of Compost Produced by an Organic Compost Machine:

Agriculture and Farming: The compost produced by an organic compost machine is a valuable resource for agriculture and farming. It enriches the soil with essential nutrients, enhances soil structure, and improves water retention. The application of compost boosts crop productivity, reduces the reliance on synthetic fertilizers, and promotes sustainable farming practices.

Gardening and Landscaping: Compost produced by an organic compost machine is highly beneficial for gardening and landscaping. It improves soil health, enriches plant beds and containers, and enhances the growth and vitality of flowers, vegetables, and ornamental plants. Compost can be used as a top dressing, mixed into potting soil, or applied as mulch to promote plant growth and suppress weed growth.

Restoration and Land Rehabilitation: Compost plays a crucial role in land rehabilitation projects. It helps restore degraded soils, erosion-prone areas, and mining sites by improving soil structure, promoting vegetation establishment, and enhancing soil nutrient content. Compost produced by an organic compost machine aids in ecosystem restoration and contributes to sustainable land management practices.

Greenhouse and Nursery Operations: Compost produced by an organic compost machine is widely used in greenhouse and nursery operations. It serves as a valuable ingredient in potting mixes, providing organic matter, improving moisture retention, and enhancing nutrient availability for young plants. Compost promotes healthy root development, reduces transplant shock, and supports successful seedling propagation.

The utilization of an organic compost machine offers numerous benefits, including waste reduction, nutrient recycling, soil improvement, and cost savings. By converting organic waste into nutrient-rich compost, this technology contributes to sustainable waste management practices, enhances soil fertility, and promotes eco-friendly agriculture and gardening. The compost produced by an organic compost machine finds applications in various sectors, including agriculture, gardening, land rehabilitation, and nursery operations.