One of Hottest for Fertilizer Machine - The manufacturers of duck manure organic fertilizer mixer – YiZheng

One of Hottest for Fertilizer Machine - The manufacturers of duck manure organic fertilizer mixer – YiZheng Detail:

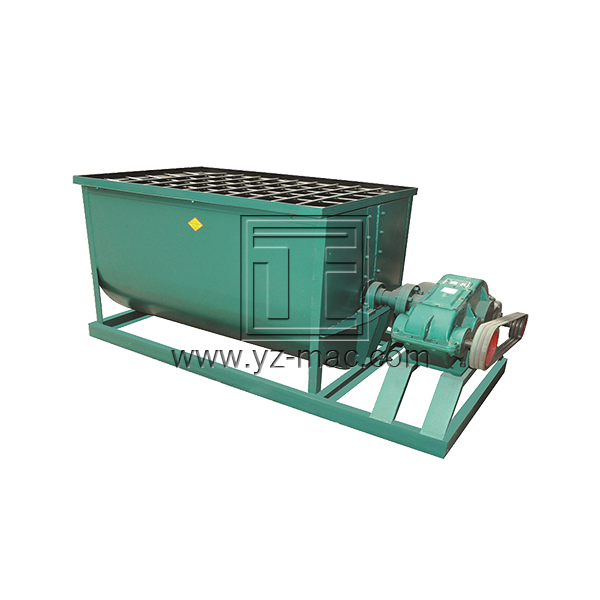

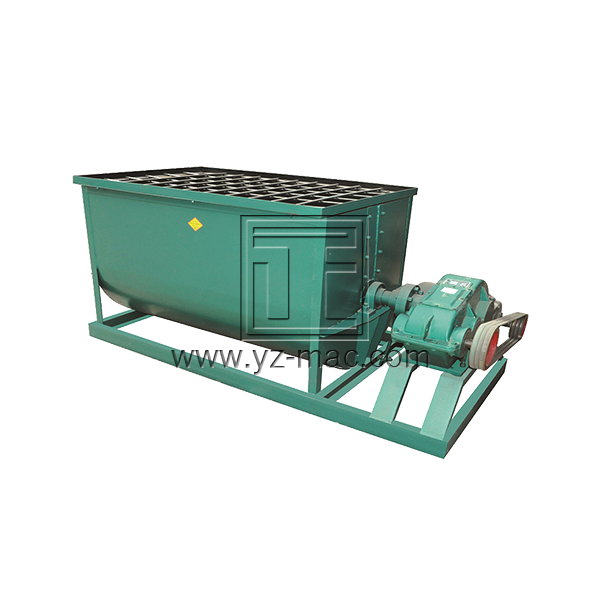

Our company produces different mixers such as dual-shaft mixers, horizontal mixers, pan mixers, BB fertilizer (blended fertilizer) mixers, forced mixers, etc. Customers can choose according to the actual composting materials, sites and products.

Horizontal mixer is a fertilizer production mixing equipment with high mixing degree and low residual amount. It is suitable for mixing more than two kinds of fertilizers, additive premix, and mixing of compound feed, concentrated feed, additive premix feed, etc. The horizontal mixer blends all the raw materials for the production of fertilizer in the mixer to achieve the overall mixing state.

Horizontal Fertilizer Mixer Model Selection:

|

Model |

Capacity(t/h) |

Power (kw) |

Speed (r/min) |

|

YZJBWS 600×1200 |

1.5-2 |

5.5 |

45 |

|

YZJBWS 700×1500 |

2-3 |

7.5 |

45 |

|

YZJBWS 900×1500 |

3-5 |

11 |

45 |

|

YZJBWS 1000×2000 |

5-8 |

15 |

50 |

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/horizontal-fertilizer-mixer-2-product/

Product detail pictures:

Related Product Guide:

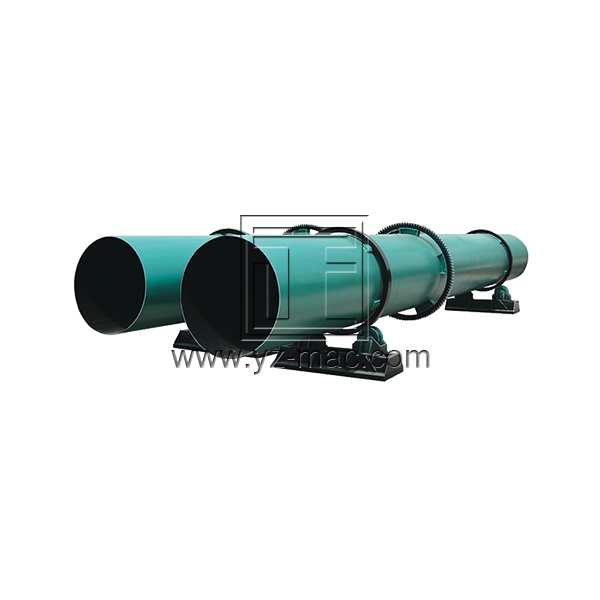

Complete production equipment for organic fertilizer

Pig manure organic fertilizer complete equipment

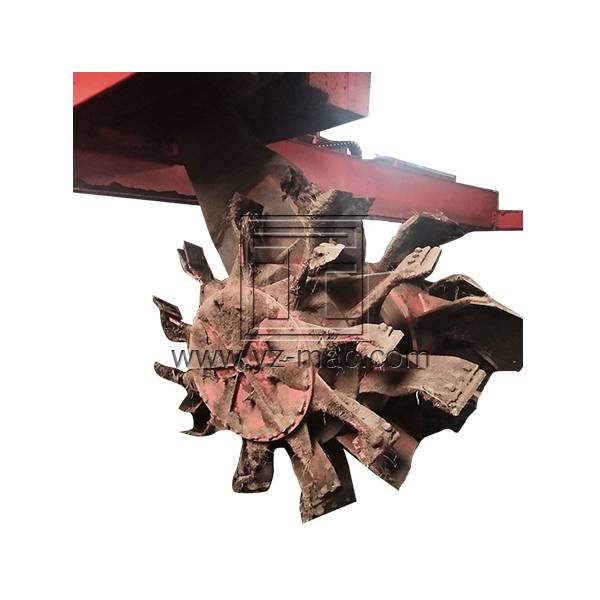

The double-screw turning machine is used for the fermentation and turning of organic wastes such as livestock and poultry manure, sludge waste, sugar mill filter mud, slag cake and straw sawdust. It is suitable for aerobic fermentation and can be combined with solar fermentation chamber, Fermentation tank and moving machine are used together. One of Hottest for Fertilizer Machine - The manufacturers of duck manure organic fertilizer mixer – YiZheng , The product will supply to all over the world, such as: Bulgaria, Macedonia, Adelaide, The vermicompost screening machine is mainly used for the separation of finished fertilizer products and returned materials. After screening, the organic fertilizer particles with uniform particle size are transported to the automatic packaging machine through the belt conveyor for weighing and packaging, and the unqualified particles are sent to the crusher. After re-grinding and then re-granulating, the classification of products is realized and the finished products are evenly classified, which is an indispensable equipment in fertilizer production.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.