OEM/ODM Factory Fertilizer Weigh Fill Machine - Screw Extrusion Solid-liquid Separator – YiZheng

OEM/ODM Factory Fertilizer Weigh Fill Machine - Screw Extrusion Solid-liquid Separator – YiZheng Detail:

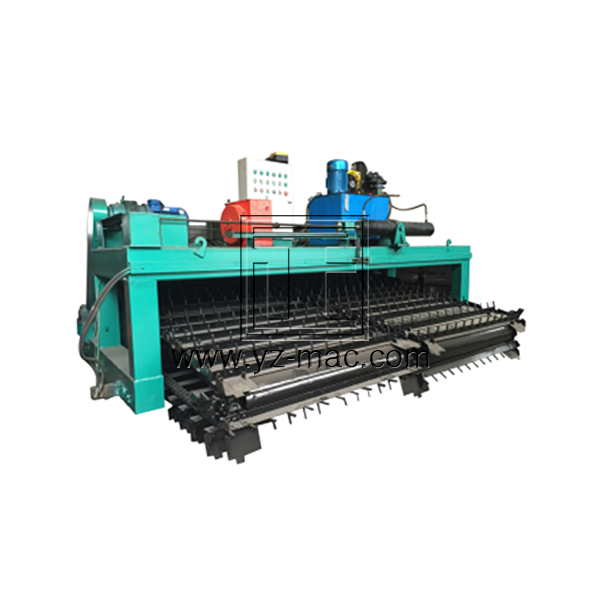

The Screw Extrusion Solid-liquid Separator is a new mechanical dewatering equipment developed by referring to various advanced dewatering equipment at home and abroad and combining with our own R&D and manufacturing experience. The Screw Extrusion Solid-liquid Separator is mainly composed of control cabinet, pipeline, body, screen, extruding screw, reducer, counterweight, unloading device and other parts, this equipment is well recognized and widely used in the market.

1. Solid manure after separation is conducive to transportation and higher price for sale.

2. After the separation, the manure is mixed into the grass bran to stir well, it can be made into compound organic fertilizer after granulation.

3. The separated manure can be directly used to improve soil quality, and it can also be used to breed earthworms, grow mushrooms and feed fish.

4. The separated liquid can directly enter the biogas pool, the biogas production efficiency is higher, and the biogas pool will not be blocked to prolong the service life.

1. Material is pumped to main motor by non-blocking slurry pump

2. Conveyed to front part of machine by squeezing auger

3. Under the filtering of edge pressure belt, water will be extruded and discharged from mesh screen and out of water pipe

4. Meanwhile, the front pressure of auger keeps increasing. When it reaches certain value, the discharge port will be pushed open for solid output.

5. In order to get the speed and water content of the discharge, the control device in front of the main engine can be adjusted to achieve a satisfactory and appropriate discharge state.

(1) It has a wide range of applications. Can be used for chicken manure, pig manure, cow manure, duck manure, sheep manure and other dung.

(2) It is also applicable to all kinds of large and small types of farmers or people engaged in animal husbandry.

(3) The main part of Screw Extrusion Solid-liquid Separator machine is designed in stainless steel, compared with other materials, stainless steel is not easy to rust, corrosion, service life longer.

|

Model |

LD-MD200 |

LD-MD280 |

|

Power |

380v/50hz |

380v/50hz |

|

Size |

1900*500*1280mm |

2300*800*1300mm |

|

Weight |

510kg |

680kg |

|

Diameter of filter mesh |

200mm |

280mm |

|

Diameter of inlet for pump |

76mm |

76mm |

|

Overflow diameter |

76mm |

76mm |

|

Liquid discharging port |

108mm |

108mm |

|

Filter mesh |

0.25,0.5mm,0.75mm,1mm |

|

|

Material |

Machine body is made of casting iron, Auger shaft and blades are made of stainless steel 304, filter screen is made of wedge stainless steel 304. |

|

|

Feeding Method |

1. Feeding with pump for liquid state material 2. Feeding with hopper for solid state material |

|

|

Capacity |

Pig manure 10-20ton/h Dry pig manure:1.5m3/h |

Pig manure 20-25m3/h Dry manure: 3m3/h |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Pig manure organic fertilizer complete equipment

Strengthen the utilization and input of organic fertilizer resources and increase the yield of land - organic fertilizer is an important source of soil fertility and the basis for crop yield. OEM/ODM Factory Fertilizer Weigh Fill Machine - Screw Extrusion Solid-liquid Separator – YiZheng , The product will supply to all over the world, such as: Nigeria, Singapore, Roman, Fertilizer granulator machine price

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.