OEM Factory for Urea Granulator - Flat-die Extrusion granulator – YiZheng

OEM Factory for Urea Granulator - Flat-die Extrusion granulator – YiZheng Detail:

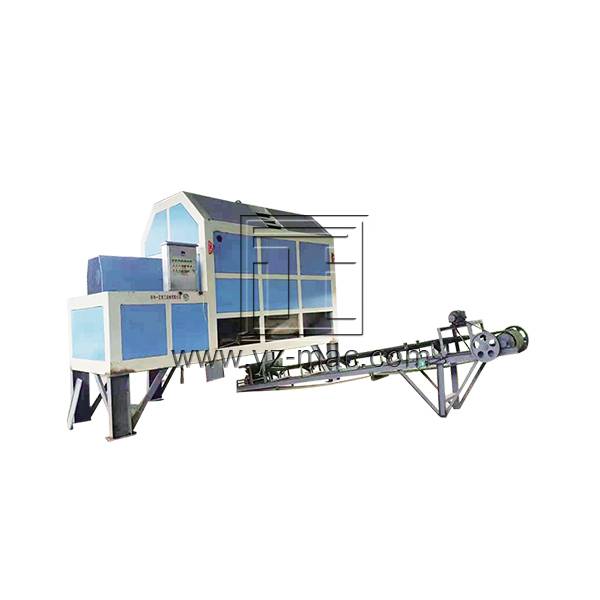

Flat Die Fertilizer Extrusion Granulator Machine is designed for different type and series. The flat die granulator machine uses the straight guide transmission form, which makes the roller self-rotating under the action of frictional force. The powder material is extruded from the hole of the mold press by the roller, and the cylindrical pellets come out through the disc. Flat Die Fertilizer Extrusion Granulator Machine is an important equipment in fertilizer industry, it is suitable for large-scale production.

Flat Die Fertilizer Extrusion Granulator Machine is to be designed and used in different type fertilizer production line. And in most of time, it is to be designed and used in the organic fertilizer and compound fertilizer production line. We are as the professional fertilizer machine manufacturers, we are not only supply the single fertilizer granulator machine, but also can design the complete fertilizer production line for different customers. In the fertilizer production line, it is to be equipped with the fertilizer granulator machine with the flat die granulator machine and the ball shaping machine to make the fertilizer granulator into ball shape.

During the operating, the materials are squeezed to the bottom by the roller, then cut off by the scraper, and then into the two-stage combined polishing, rolling into the ball. The Flat Die Fertilizer Extrusion Granulator Machine has the advantages of high pellet forming rate, no returning material, high granule strength, uniform roundness, low granule moisture and less drying energy consumption.

1. This machine is mainly used for granule processing of biological organic fertilizer and feed processing industry.

2. The granules processed by Flat Die Fertilizer Extrusion Granulator Machine have smooth and clean surface, moderate hardness, low temperature rising during the process, and can keep the nutrients of the raw materials very well.

3. Uniform granules, the diameter of granules can be divided into: Φ 2, Φ 2.5, Φ3.5, Φ 4, Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to actual needs.

4. Granule moisture content is low and suitable for storage and transportation, so it greatly improved the material utilization rate.

- ►The finished product granule cylindrical.

- ►The organic content can be up to 100%, make pure organic granulate

- ►Using organic matter granule with mutual mosaic and becoming larger under a certain force, it no need to add binder when granulating.

- ►With durable product granule, it can sieve directly after granulation to reduce the energy consumption of drying

- ►After fermentation organics don’t need to dry, moisture of the raw material can be in 20%-40%.

|

Model |

YZZLPM-150C |

YZZLPM-250C |

YZZLPM-300C |

YZZLPM-350C |

YZZLPM-400C |

|

Production (t/h) |

0.08-0.1 |

0.5-0.7 |

0.8-1.0 |

1.1-1.8 |

1.5-2.5 |

|

Granulating rate (%) |

>95 |

>95 |

>95 |

>95 |

>95 |

|

Granule temperature rise (℃) |

<30 |

<30 |

<30 |

<30 |

<30 |

|

Power (kw) |

5.5 |

15 |

18.5 |

22 |

33 |

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Pig manure organic fertilizer complete equipment

Mechanical composting is mainly to carry out high-temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, and use the activity of microorganisms to decompose the organic matter in the waste to achieve harmlessness, stabilization and reduction. Integrated sludge treatment equipment for quantitative and resource utilization. OEM Factory for Urea Granulator - Flat-die Extrusion granulator – YiZheng , The product will supply to all over the world, such as: Sheffield, Washington, Puerto Rico, Dry granulation equipment

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.