NPK fertilizer machine

An NPK fertilizer machine is a specialized equipment designed for the production of NPK fertilizers, which are essential for supplying essential nutrients to crops. NPK fertilizers contain a balanced combination of nitrogen (N), phosphorus (P), and potassium (K) in varying ratios, catering to different crop requirements.

Importance of NPK Fertilizers:

NPK fertilizers play a crucial role in ensuring optimal crop growth and productivity. Each nutrient in the NPK formulation contributes to specific plant functions:

Nitrogen (N) promotes vegetative growth, leaf development, and protein synthesis.

Phosphorus (P) supports root development, flowering, and fruiting, as well as energy transfer within the plant.

Potassium (K) enhances overall plant vigor, disease resistance, water regulation, and nutrient uptake.

Working Principle of NPK Fertilizer Machines:

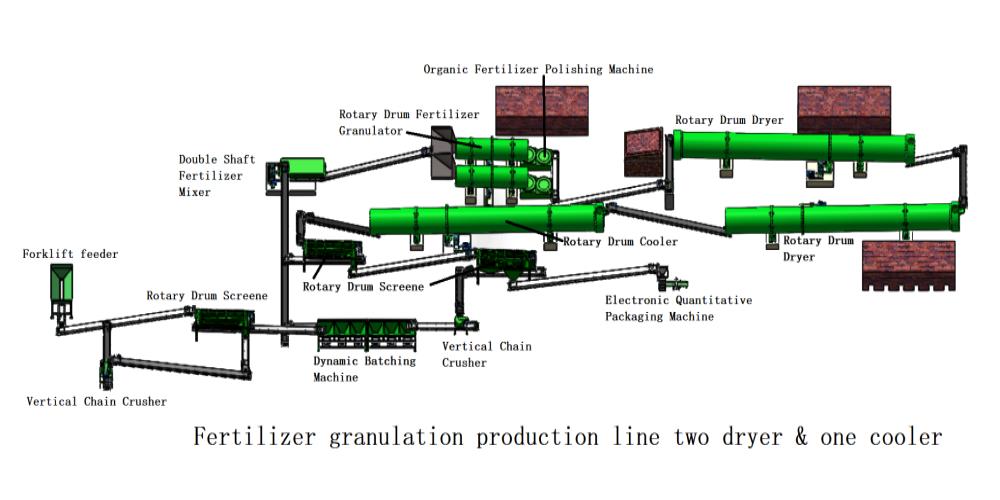

NPK fertilizer machines are designed to blend and granulate the individual nutrient components, resulting in a homogeneous NPK fertilizer product. The machines utilize various processes such as mixing, crushing, granulating, and drying to achieve the desired formulation and granule size. The production process may involve the use of raw materials like urea, ammonium phosphate, potassium chloride, and other nutrient sources, which are mixed and processed to create the final NPK fertilizer product.

Applications of NPK Fertilizer Machines:

Agriculture and Crop Production:

NPK fertilizer machines are extensively used in agriculture to produce customized NPK fertilizers that meet specific crop nutrient requirements. These machines enable precise control over the nutrient composition, allowing farmers to tailor fertilizers according to soil conditions, crop types, and growth stages. By providing the right balance of NPK nutrients, these machines contribute to improved crop yields, quality, and overall agricultural sustainability.

Horticulture and Floriculture:

In horticultural and floricultural practices, NPK fertilizers are essential for promoting healthy plant growth, vibrant blooms, and robust root systems. NPK fertilizer machines enable the production of specialized formulations tailored to the specific needs of ornamental plants, trees, shrubs, and greenhouse crops. These fertilizers provide the necessary nutrients for optimal growth, aesthetics, and market value of horticultural and floricultural products.

Turf and Lawn Management:

NPK fertilizers are widely used in turf and lawn care for maintaining lush green grass and strong root systems. NPK fertilizer machines facilitate the production of granular or liquid fertilizers suitable for golf courses, sports fields, public parks, and residential lawns. These fertilizers help achieve uniform growth, disease resistance, and proper nutrient balance for healthy turf and attractive landscapes.

Specialty Crop Cultivation:

Certain specialty crops, such as fruits, vegetables, and cash crops, have specific nutrient requirements that can be met with customized NPK fertilizers. NPK fertilizer machines enable the production of tailored formulations to meet the unique nutritional demands of specialty crops, enhancing their growth, yield, quality, and marketability.

NPK fertilizer machines play a vital role in ensuring balanced crop nutrition by producing customized NPK fertilizers. These machines blend and granulate the essential NPK nutrients, providing precise control over the nutrient composition and granule size.